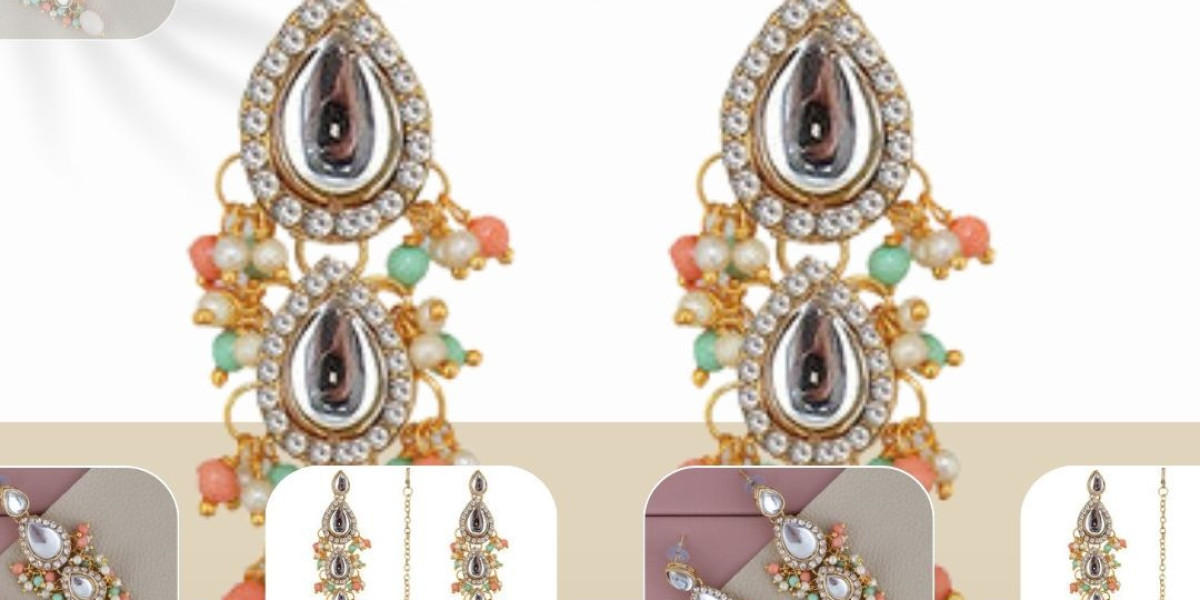

Shop Lucky Jewellery in Lucknow for stunning Kundan earrings and tikka sets. Elegant, gold-plated & perfect for any occasion. Order online now at ZillyBuy. Step into fashion.

Shop Lucky Jewellery in Lucknow for stunning Kundan earrings and tikka sets.

Shop Lucky Jewellery in Lucknow for stunning Kundan earrings and tikka sets. Elegant, gold-plated & perfect for any occasion. Order online now at ZillyBuy. Step into fashion.