Industry 4.0 2024

Industry 4.0, often referred to as the fourth industrial revolution, is reshaping the manufacturing landscape through the integration of advanced technologies like the Internet of Things (IoT), artificial intelligence (AI), big data, and automation. These technological advancements are transforming industries by creating smarter, more connected, and highly efficient systems. Industry 4.0 Market Trends show an increasing adoption of these innovative technologies, as manufacturers seek to improve productivity, reduce costs, and enhance product quality. The shift toward smart factories, where machines, devices, and systems are interconnected and capable of communicating with one another, is central to this transformation, making processes more efficient and responsive in real-time.

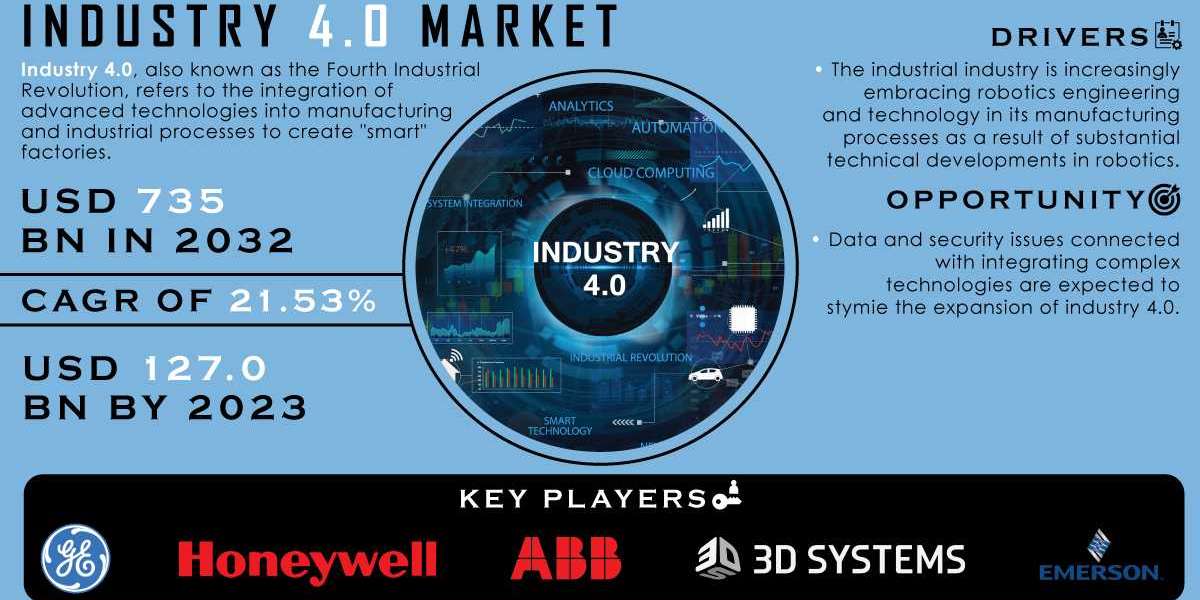

Industry 4.0 Market was valued at USD 166.1 billion in 2023 and is expected to grow to USD 862.0 billion by 2032, growing at a CAGR of 20.1% over the forecast period of 2024-2032. This remarkable growth reflects the accelerating pace at which industries are adopting digital technologies to meet the demands of modern manufacturing, logistics, and supply chain management.

What is Industry 4.0?

Industry 4.0 represents a new era of manufacturing and industrial production that is driven by digital technologies. The term originated from a German government initiative aimed at promoting computerization in manufacturing. The core idea behind Industry 4.0 is the creation of “smart factories” that are highly automated, data-driven, and connected. Through the use of sensors, robots, AI, and data analytics, businesses can optimize their operations by achieving greater flexibility, efficiency, and precision in production processes.

At the heart of Industry 4.0 is the concept of cyber-physical systems (CPS), which blend physical processes with digital systems. This integration allows for real-time monitoring and control of production, making processes more transparent and adaptable. Through connected devices and sensors, manufacturers can gather vast amounts of data, which can then be analyzed to make informed decisions, predict failures before they occur, and ensure better resource utilization.

Key Technologies Driving Industry 4.0

Several key technologies are propelling the growth of Industry 4.0. The Internet of Things (IoT) plays a crucial role by connecting machines, systems, and devices to the internet, allowing for constant communication and data exchange. These IoT-enabled devices can provide real-time data on equipment performance, inventory levels, and production processes, enabling quick adjustments to optimize operations.

Automation and robotics are also central to Industry 4.0. Smart robots are increasingly being used in manufacturing facilities to perform repetitive or hazardous tasks, allowing human workers to focus on higher-value activities. These robots are often autonomous, able to make decisions based on data collected from sensors and AI algorithms.

AI and machine learning are another critical component of Industry 4.0. By using advanced algorithms to analyze large volumes of data, AI can identify patterns, predict trends, and optimize processes. In manufacturing, AI can assist in everything from quality control to predictive maintenance, reducing downtime and improving product quality.

Impact on Industries

The impact of Industry 4.0 is far-reaching, extending beyond manufacturing and into sectors like healthcare, logistics, and energy. In the healthcare industry, Industry 4.0 technologies enable better patient care through the use of IoT devices that monitor patient vitals in real-time, AI-powered diagnostics tools, and data analytics platforms that improve clinical decision-making.

In logistics and supply chain management, Industry 4.0 technologies are enhancing efficiency through automation and data-driven decision-making. For example, autonomous vehicles and drones are being used to transport goods, while predictive analytics help businesses anticipate demand and optimize inventory.

Additionally, the energy sector benefits from Industry 4.0 through the optimization of power grids, energy consumption, and the integration of renewable energy sources. Smart grids and energy storage systems are just a few examples of how these technologies are helping to create more sustainable and efficient energy systems.

Challenges and Considerations

Despite the numerous benefits, the implementation of Industry 4.0 comes with challenges. One major concern is the cost of adopting advanced technologies. For many smaller manufacturers, the initial investment in IoT devices, AI systems, and automation tools can be prohibitive. Additionally, the integration of new technologies into existing systems can be complex and time-consuming, requiring significant changes to both hardware and software infrastructure.

Data security and privacy are also significant concerns, as the increased connectivity of devices and systems opens up potential vulnerabilities to cyberattacks. To mitigate these risks, businesses must invest in robust cybersecurity measures and ensure that their systems are regularly updated to address emerging threats.

The Future of Industry 4.0

As Industry 4.0 continues to evolve, its potential to transform industries is boundless. Advancements in AI, 5G, and quantum computing will further enhance the capabilities of cyber-physical systems, creating even smarter and more efficient factories. The future of manufacturing is poised to be more flexible, responsive, and sustainable, with the continued adoption of Industry 4.0 technologies driving innovation across industries.

In conclusion, Industry 4.0 is reshaping the way businesses operate, offering significant improvements in efficiency, productivity, and quality. With the continued development of cutting-edge technologies and the increasing adoption of digital solutions, the future of manufacturing and beyond is set to be transformed. As industries embrace Industry 4.0, they will unlock new opportunities for growth, sustainability, and competitiveness.

Contact Us:

Akash Anand – Head of Business Development Strategy

info@snsinsider.com

Phone: +1-415-230-0044 (US) | +91-7798602273 (IND)

About Us

SS Insider is one of the leading market research and consulting agencies that dominates the market research industry globally. Our company's aim is to give clients the knowledge they require in order to function in changing circumstances. In order to give you current, accurate market data, consumer insights, and opinions so that you can make decisions with confidence, we employ a variety of techniques, including surveys, video talks, and focus groups around the world.

Read Our Other Reports: