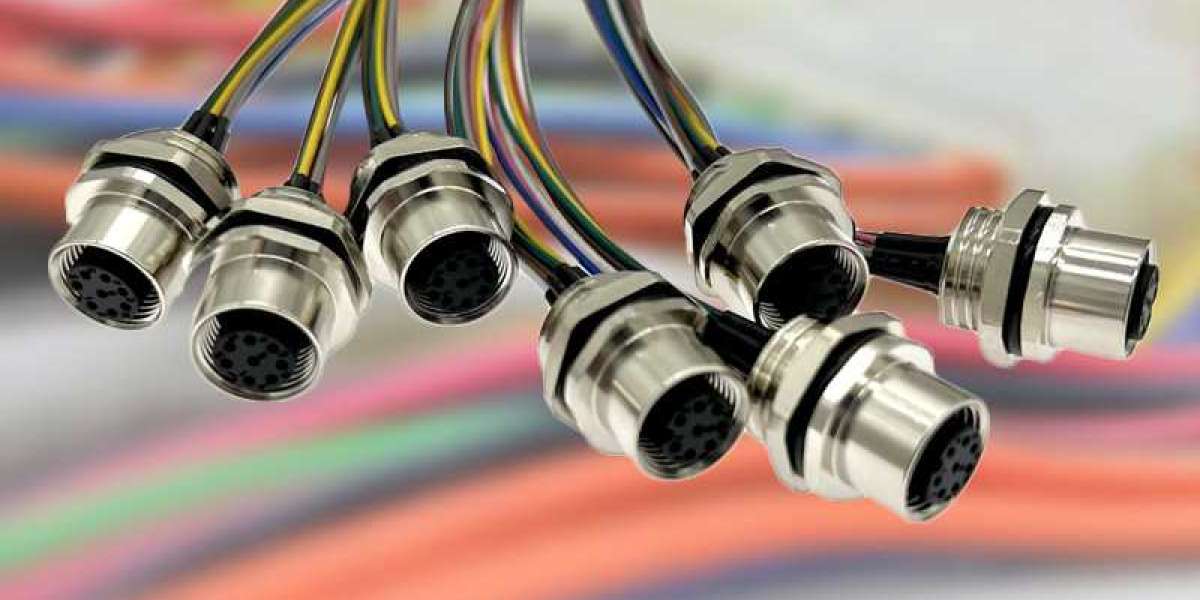

Vietnam is fast becoming a key player in the global cable manufacturing industry, offering a mix of cost-effectiveness and quality. However, the sheer number of cable manufacturers in Vietnam can make it challenging to identify the right partner. It’s essential to look for warning signs to ensure a successful collaboration. This blog highlights the top five red flags to help you make an informed choice.

Lack of Certifications and Compliance Standards

A manufacturer’s adherence to international standards is critical for their credibility. Certifications like ISO 9001, ISO 14001, or CE marking demonstrate that the company meets global safety, environmental, and quality benchmarks. If a supplier cannot provide proof of certifications or lacks proper compliance documentation, it’s a significant red flag. These certifications are vital for telecommunications, construction, and automotive, where cable quality directly affects operational safety and efficiency.

When sourcing from cable manufacturers in Vietnam, always verify their compliance with industry standards and ensure their certifications are up to date. Doing so will help you avoid potential legal and operational issues.

Poor Communication and Transparency

A good business relationship is built on effective communication. It could cause major problems later on if your potential supplier needs assistance in providing clear information about their procedures, delivery schedules or product specs. A lack of transparency often signals disorganization or attempts to hide flaws in production capabilities. Reliable cable manufacturers in Vietnam maintain open communication channels, providing regular updates on order progress and addressing concerns promptly.

Top-tier cable manufacturers in Vietnam typically go the extra mile to keep clients informed, whether it’s through real-time production tracking, factory audits, or detailed documentation.

Limited Customization Options

Every industry is different, and companies frequently need cables made for their particular uses. To meet specialized needs, a manufacturer who refuses to offer customization may require additional technical know-how or sophisticated machinery. Customization entails creating cables with specific compositions, thicknesses, conductivities or insulating qualities to meet your demands. There needs to be more options of this kind to avoid poor performance or incompatibilities.

Companies like SINNHONG ELECTRONICS CO., LIMITED, set themselves apart by offering flexible solutions tailored to client demands. They understand that customization builds long-term relationships and meets diverse industry needs.

Inconsistent Quality Control Processes

When selecting a cable manufacturer, inconsistent quality is a deal-breaker. Poor cables can result in higher maintenance expenses, system failures, and operational outages. Examine the supplier's quality control procedures before signing a contract. Request documents outlining their testing and inspection processes, or ask for product samples. Manufacturers with strong quality control systems will be happy to provide this information.

Leading cable manufacturers in Vietnam invest in advanced testing equipment and employ skilled professionals to ensure every product meets client expectations. Look for signs of reliability such as automated production lines and comprehensive post-production inspections.

Unrealistically Low Prices

Although purchasing from Vietnam has several benefits including cost reductions, low costs should raise suspicions. By utilizing subpar materials, omitting necessary tests or outsourcing to unregulated subcontractors, manufacturers offering costs significantly below market rates may take shortcuts. These savings frequently have unstated consequences such as a product's poor durability, delayed shipping or higher replacement and maintenance costs.

Opt for manufacturers who balance competitive pricing with quality assurance. For example SINNHONG ELECTRONICS CO., LIMITED offers fair pricing without compromising material quality or delivery timelines ensuring clients get maximum value for their investment.

Bonus Tip: Vetting Manufacturers Through On-Site Visits

Nothing compares to a comprehensive on-site assessment, even though the red flags listed above are useful. You can evaluate the manufacturer's production capacity, quality standards and working conditions in advance by visiting the factory. It also aids in evaluating the professionalism and dedication to openness of the business. If a firm restricts your access to their facilities or discourages factory tours, it may be a sign of deeper problems.

Why Careful Selection of Cable Manufacturers in Vietnam Matters

Choosing the right cable manufacturers in Vietnam is more than just securing a supplier; it’s about building a reliable partnership that supports your business goals. Working with the wrong manufacturer can lead to delayed projects, reputational damage, or even safety hazards. By identifying and avoiding these red flags, you’ll be better equipped to select a manufacturer that delivers quality, reliability, and value.

The cable manufacturing industry in Vietnam offers vast opportunities, but finding the right partner requires due diligence. Search manufacturers that are certified, transparent and adaptable to your needs. Avoid those that cut corners, overpromise, or fail to maintain consistent quality standards. Reliable companies like SINNHONG ELECTRONICS CO., LIMITED, stand out by prioritizing customer satisfaction and adhering to the highest quality benchmarks.