The energy storage startup founder’s dilemma is all too familiar: You’ve nailed the battery chemistry for your home energy system, but your prototype line can only churn out 50 units/day. Scale up with a rigid mass-production line, and you risk getting stuck with $2M+ equipment if your next-gen design requires tweaks. Stay small, and you’ll miss the window to capture government subsidies or partner with EV OEMs.

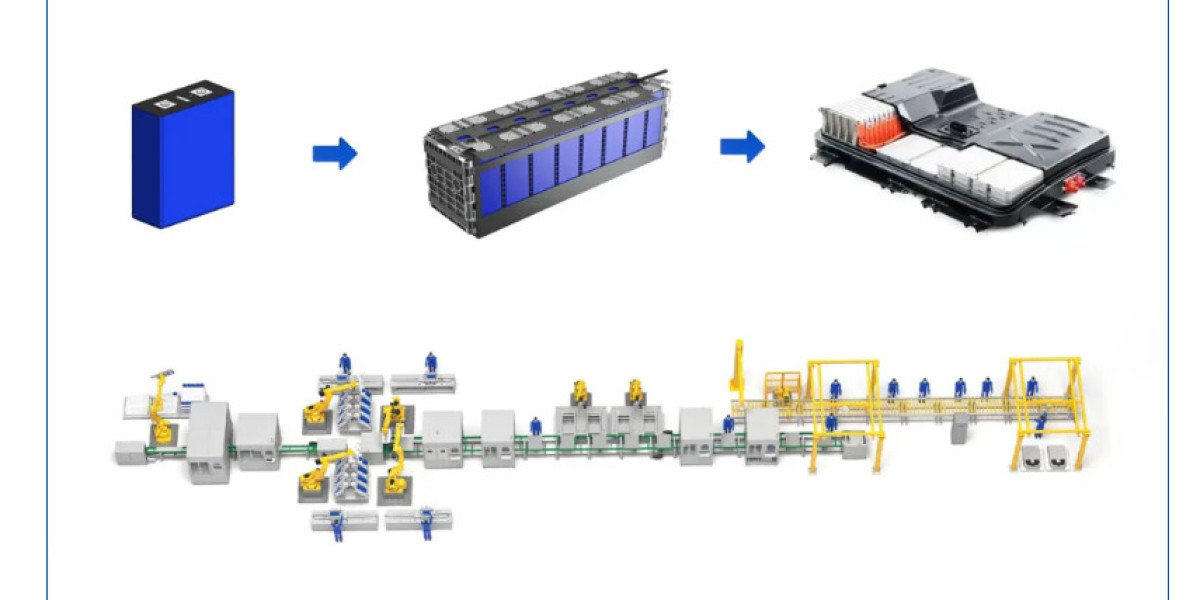

As a manufacturer specializing in prismatic battery pack assembly lines for over a decade, we’ve watched dozens of promising startups hit this wall. The solution, it turns out, isn’t choosing between “small batch” and “scale”—it’s reimagining the assembly line itself. Here’s how modular automation is letting teams achieve 99.9% yield rates and iterate on battery designs in weeks, not quarters.

The Hidden Cost of “One-Size-Fits-All” Production Lines

Traditional battery assembly lines are built for (think: CATL or Tesla) churning out 100k+ units/year of identical packs. For a startup building niche products—say, a high-temperature battery for desert solar storage or a lightweight pack for delivery drones—these lines become liabilities:

Changeover hell: Swapping from a 1kWh home storage pack to a 5kWh commercial unit can take 8+ hours of downtime, killing agility.

Over-engineering: Why pay for a 30PPM line (30 packs/minute) when you only need 5PPM right now? Most startups end up with 70% unused capacity.

Rigid specs: Your prismatic lithium iron phosphate cells need a custom welding pattern? Good luck convincing a standard line to deviate from its pre-programmed parameters.

The Modular Fix: How to Build a Line That Grows With You

Our square battery pack assembly lines were designed specifically to solve this paradox. Here’s how the tech works for early-stage teams:

1. Plug-and-play modules let you start small and scale incrementally. A basic setup (cell sorting + laser welding + EOL testing) fits in 300 sqm and costs 60% less than a full line—perfect for startups shipping 1k-10k units/year. Add modules (like liquid cooling plate gluing or helium leak testing) as demand grows, with zero reconfiguration downtime.

2. 15-minute changeovers via “recipe libraries”. Store parameters for 50+ battery designs (different cell types, pack sizes, chemistries) in the MES system. Swap from a 24V drone battery to a 48V home storage pack with a single click—no mechanical retooling needed. One EU-based startup used this to test 3 iterations of their sodium-ion pack in 2 months, cutting R&D time by 40%.

3. Precision that doesn’t sacrifice speed. Even with flexibility, the line hits 12-30PPM (modules/packs per minute) with ±0.2mm repeat accuracy—critical for prismatic cells where misalignment can slash cycle life by 30%. Our vision inspection system replaces 4 manual check stations, catching defects (like micro-cracks in busbars) that human eyes miss 2% of the time.

When Startups Meet “Big Factory” Reliability: A Real-World Example

Take the case of a California-based energy storage startup we worked with last year. They needed to produce both:

A high-volume 10kWh residential pack (500 units/week)

A low-volume 50kWh commercial pack (20 units/week for pilot projects)

Their initial plan? Two separate lines. Instead, they opted for our modular setup:

Shared core modules: Cell loading, OCV testing, and EOL systems handled both pack types.

Dedicated change parts: Quick-swap fixtures for busbar welding and casing assembly.

MES integration: Real-time data tracking let them tweak the commercial pack’s cooling layout after 10 units, based on thermal test feedback.

Result? They launched both products 3 months ahead of schedule, with a capital expenditure 35% lower than planned. And when their residential pack won a utility contract requiring 2x volume, they added a second welding module in 3 days—no factory shutdown required.

To the Product Hunt Community: What’s Your Production Bottleneck?

We’ve built these lines for everyone from EV startups in Vietnam to drone manufacturers in Germany, but the core challenge remains universal: How do you balance “move fast” with “build right” in battery production?

If you’re scaling a battery product now, what’s your biggest obstacle—cost, flexibility, or compliance?

Have you tried modular automation before? What worked (or didn’t)?

For hardware founders: When did you decide it was time to invest in custom production equipment vs. outsourcing?

As a national high-tech enterprise with 200+ R&D engineers, we’re happy to share more details on cell-to-pack processes, laser welding parameters, or EU/US compliance hacks—just drop a question below. Let’s build a thread that helps the next wave of energy innovators avoid the “scale or die” trap.