Metrology Software 2024

In today’s rapidly advancing technological landscape, precision and accuracy are vital for ensuring the quality of products across industries such as manufacturing, aerospace, automotive, and healthcare. Metrology software plays a crucial role in this by providing solutions for measurement, inspection, and quality control. These software platforms are designed to enhance the precision of measurements, reduce errors, and ensure consistency in manufacturing processes. Metrology Software Market Trends indicate a growing reliance on digital solutions for metrology, particularly in industries where high standards of accuracy are required. The increasing need for improved quality control, regulatory compliance, and the rise of Industry 4.0 are driving the adoption of these software solutions.

Metrology software integrates with advanced measurement equipment such as coordinate measuring machines (CMM), laser scanners, and optical measurement devices. By automating data collection and analysis, these systems help to streamline the measurement process, enabling companies to conduct more efficient inspections and reduce manual effort. This integration of digital tools with physical measurement devices ensures a higher level of precision and speed, allowing manufacturers to detect defects early and improve overall product quality. Whether in product design, quality assurance, or reverse engineering, metrology software is essential for a wide range of applications, ensuring that the final products meet the required specifications.

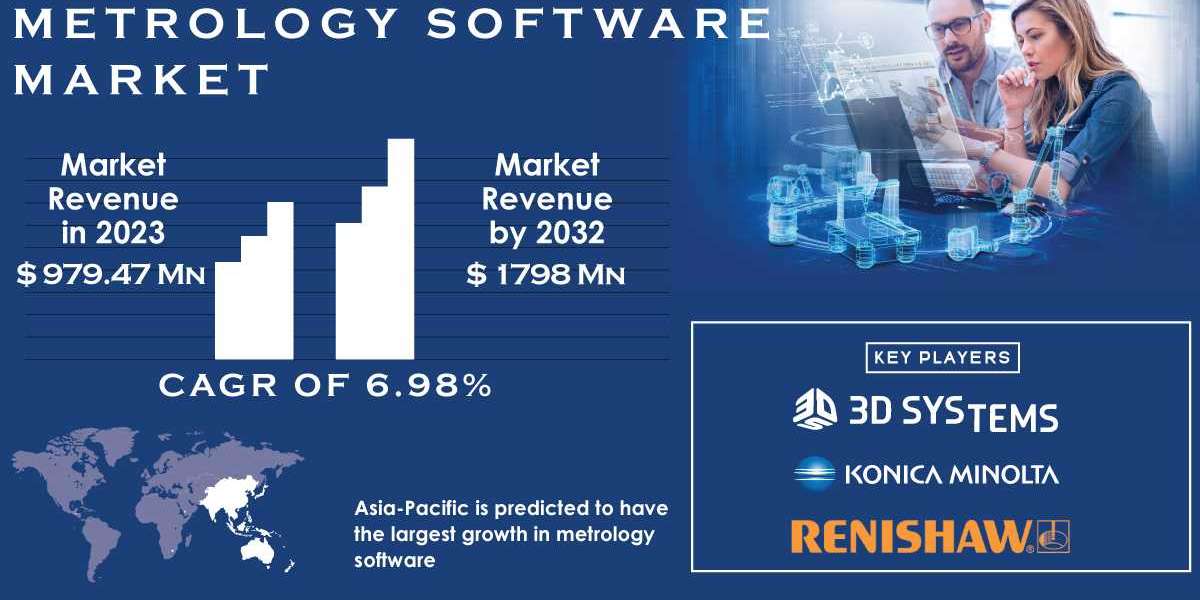

Metrology Software Market was valued at USD 998.65 million in 2023 and is expected to reach USD 1917.53 million by 2032 and grow at a CAGR of 7.52% over the forecast period of 2024-2032.

Key Benefits of Metrology Software

One of the primary advantages of metrology software is its ability to automate and streamline the measurement process. Traditional methods of measurement often involve manual data collection and analysis, which can be time-consuming and prone to errors. With the help of metrology software, manufacturers can automate many of these tasks, allowing for faster and more accurate data processing. The ability to perform real-time analysis helps companies quickly identify discrepancies and implement corrective actions, reducing downtime and improving production efficiency.

Furthermore, metrology software provides greater flexibility in measurement techniques. It supports a variety of measurement devices, from CMMs to laser scanners and 3D vision systems, allowing manufacturers to select the best equipment for specific tasks. This flexibility ensures that companies can meet the diverse needs of their production lines and quality control processes without the need for multiple software solutions. As a result, manufacturers can reduce costs by consolidating their measurement processes under a single platform.

Applications Across Industries

Metrology software is used in a wide range of industries to ensure product quality and precision. In the automotive sector, for example, it is used to measure and inspect components such as engine parts, body panels, and safety features. High-precision measurements are necessary to ensure that all parts fit together perfectly, which is critical for vehicle safety and performance. The aerospace industry also relies on metrology software to measure and inspect complex components such as turbine blades and airframes, where even the smallest error can result in significant consequences.

In the manufacturing sector, metrology software is essential for quality control in the production of parts with intricate geometries. It allows manufacturers to verify that each part meets strict tolerances, ensuring that the final product performs as intended. The healthcare and medical device industries also benefit from metrology software, using it to inspect and validate the manufacturing of surgical instruments, implants, and other precision medical equipment.

Challenges in Adopting Metrology Software

While the benefits of metrology software are clear, there are some challenges that organizations must consider when implementing these solutions. One of the main challenges is the high initial cost of software and associated measurement equipment. Although metrology software can lead to long-term savings by improving efficiency and reducing errors, the upfront investment required for high-precision measurement tools can be significant, particularly for small and medium-sized enterprises.

Another challenge is the need for skilled personnel to operate the software and measurement devices. While the software automates many processes, it still requires users to understand how to properly set up and configure the systems, interpret data, and ensure accurate measurements. Training and ongoing education are essential for ensuring that employees can maximize the potential of metrology software and avoid errors that could compromise product quality.

The Future of Metrology Software

The future of metrology software is closely linked to advancements in digital technologies, particularly automation, artificial intelligence (AI), and the Internet of Things (IoT). As these technologies continue to evolve, metrology software will become even more intelligent and capable of performing complex measurements and analyses without human intervention. The integration of AI will enable the software to identify patterns and trends in measurement data, making predictive maintenance and quality control processes more efficient.

Furthermore, the continued growth of Industry 4.0 will likely drive the increased adoption of metrology software. As manufacturing processes become more automated and interconnected, metrology software will be essential for ensuring that all devices and systems work in harmony. The ability to integrate measurement systems into larger digital ecosystems will enable manufacturers to achieve even higher levels of efficiency, accuracy, and quality in their operations.

In conclusion, metrology software is transforming the way industries measure and manage product quality. With its ability to automate processes, improve precision, and reduce errors, it is becoming an indispensable tool for manufacturers in various sectors. As technological advancements continue to shape the future of metrology, these software solutions will play an increasingly important role in ensuring that products meet the highest standards of quality and performance.

Contact Us:

Akash Anand – Head of Business Development Strategy

info@snsinsider.com

Phone: +1-415-230-0044 (US) | +91-7798602273 (IND)

About Us

SNS Insider is one of the leading market research and consulting agencies that dominates the market research industry globally. Our company's aim is to give clients the knowledge they require in order to function in changing circumstances. In order to give you current, accurate market data, consumer insights, and opinions so that you can make decisions with confidence, we employ a variety of techniques, including surveys, video talks, and focus groups around the world.

Read Our Other Reports: