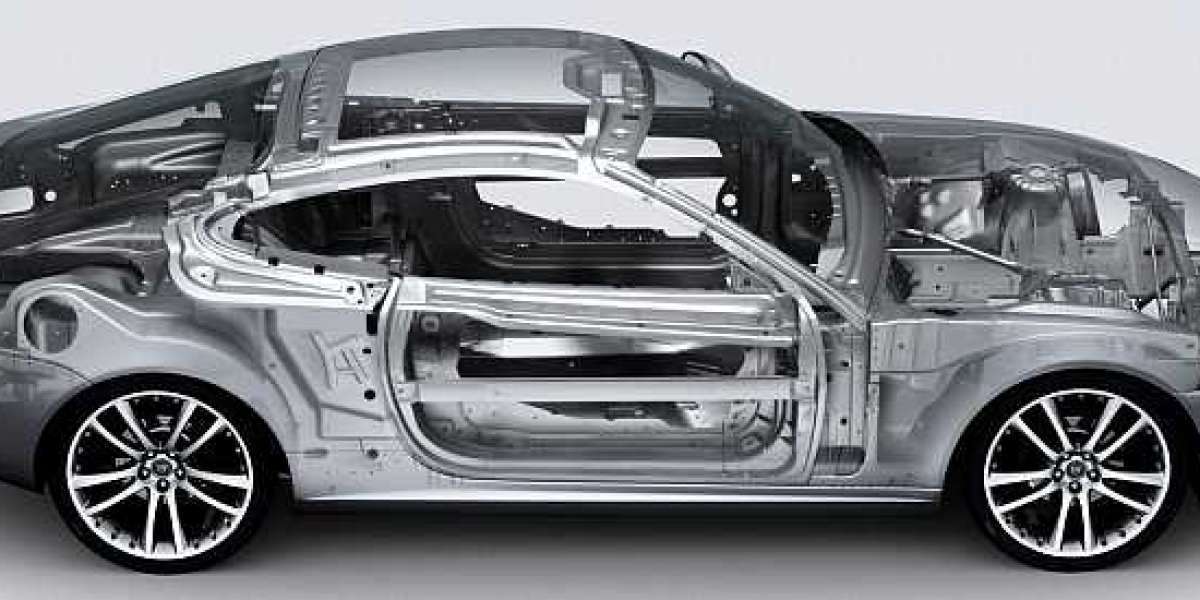

The automotive industry has seen a major shift towards using lighter weight materials in vehicle design and manufacturing over the past decade. One of the primary drivers for this has been the push for increased fuel efficiency and reduced emissions. Aluminum offers a lightweight yet strong alternative to heavier traditional steel and has increasingly become the material of choice for both body panels and chassis components.

Rise of Aluminum Use in Cars

Automakers have significantly ramped up the use of Automotive Aluminum in modern vehicles. On average, the aluminum content in a vehicle has grown from around 100 kg to over 200 kg in popular models. This trend is expected to continue further with many predicting the average aluminum content to reach 300-400 kg by 2025. Premium brands have already crossed the 500 kg mark in some luxury SUVs and pickup truck models. The engine blocks, cylinder heads, transmission cases that were traditionally made of cast iron are now being replaced with aluminum to achieve massive weight savings. Even components like wheels and suspension knuckles are incorporating more aluminum alloys.

Cost Reduction Driving Widespread Adoption

One of the main barriers that had previously limited more extensive use of aluminum in autos was its higher material cost compared to steel. However, automakers have successfully managed to bring down the costs through innovations in aluminum casting techniques, optimizing alloy compositions and leveraging economies of scale.

Explore More Related Article On- Automotive Aluminum

Get More Insights On- Automotive Aluminum