In the world of material handling and industrial automation, conveyor systems play a crucial role in streamlining operations, improving efficiency, and reducing labor costs. At the heart of these systems are conveyor components—the essential parts that ensure smooth and reliable operation. Whether you’re in manufacturing, mining, recycling, or logistics, understanding the key components of conveyor systems can help you optimize performance and minimize downtime.

Key Conveyor Components

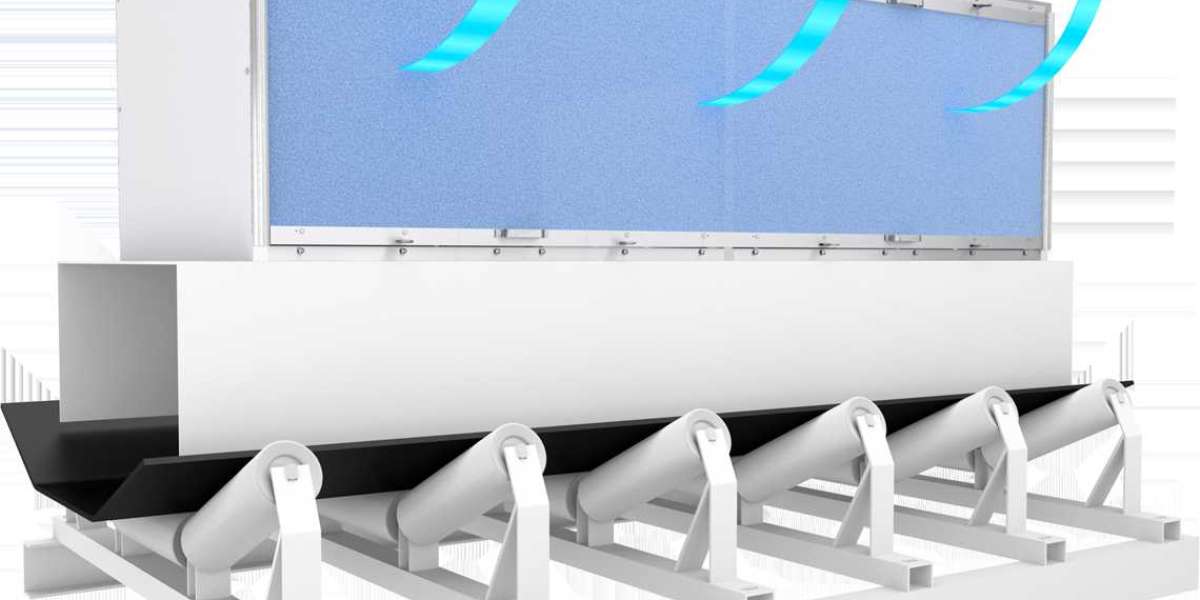

Belts: The conveyor belt is the most visible part of the system, responsible for transporting materials from one point to another. Belts come in various materials, such as rubber, PVC, or metal, depending on the application and the type of materials being handled.

Rollers: Rollers support the conveyor belt and facilitate its movement. They are available in different sizes and materials, including steel, plastic, and ceramic, to suit specific operational needs.

Pulleys: Pulleys are used to drive, redirect, or tension the conveyor belt. They are typically made of durable materials like steel and are designed to withstand heavy loads and high speeds.

Motors and Drives: These components provide the power needed to move the conveyor belt. Motors and drives come in various configurations, including electric, hydraulic, and pneumatic, depending on the system’s requirements.

Idlers: Idlers are rollers that support the belt in between the main rollers. They help maintain the belt’s alignment and prevent sagging, ensuring smooth operation.

Bearings: Bearings reduce friction between moving parts, such as rollers and pulleys, enhancing efficiency and extending the lifespan of the conveyor system.

Frame and Structure: The frame provides the structural support for the entire conveyor system. It must be sturdy and durable to handle the weight of the materials and the stress of continuous operation.

Control Systems: Modern conveyor systems often include advanced control systems, such as sensors, PLCs (Programmable Logic Controllers), and software, to automate and monitor operations.

Why Quality Matters

Investing in high-quality conveyor components is essential for ensuring the reliability and longevity of your system. Poor-quality parts can lead to frequent breakdowns, increased maintenance costs, and reduced productivity. By sourcing components from trusted suppliers like ScrapeTec Trading, you can ensure your conveyor system operates at peak performance.

ScrapeTec Trading: Your Partner for Conveyor Components

ScrapeTec Trading specializes in providing high-quality conveyor components and solutions tailored to your specific needs. With a focus on durability, efficiency, and innovation, they offer a wide range of products, including belts, rollers, pulleys, and more. Their expertise and commitment to customer satisfaction make them a trusted partner for industries worldwide.

Conclusion

Conveyor components are the backbone of any material handling system, ensuring smooth and efficient operations. By understanding the key components and investing in quality parts, you can optimize your conveyor system’s performance and minimize downtime. For reliable and innovative conveyor solutions, visit ScrapeTec Trading to explore their extensive product offerings and expert support.