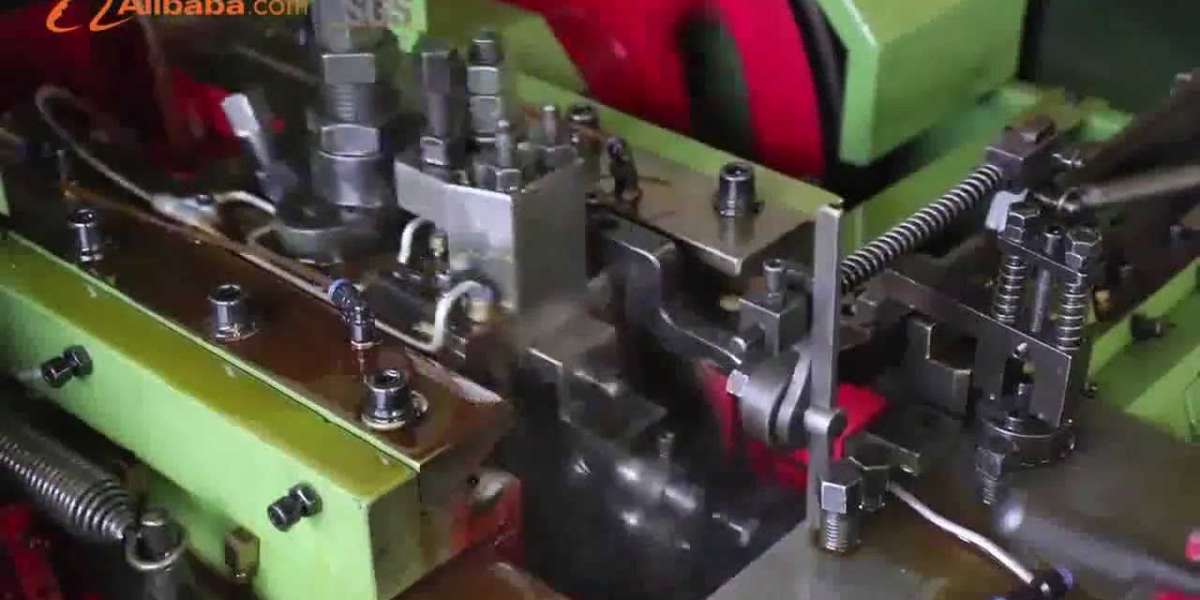

Cold Heading Machine Market Size.is a forming process that produces metal parts by compressing and extruding metal stock between a die and punch using large presses. The process involves forcing metal stock into a die cavity by hammering, pressing, or swaging action without appreciable heating of the workpiece. It offers advantages such as the production of complex net-shape parts that don't require secondary operations and ability to work with various metals. With the growing automotive, fastener and metalworking industries demanding high precision cold headed parts there is a need for efficient cold heading machines capable of heavy duty operations.

The global Cold Heading Machine Market is estimated to be valued at US$ 3.59 Billion in 2024 and is expected to exhibit a CAGR of 4.8% over the forecast period from 2024 to 2031.

Key Takeaways

Key players operating in the Cold Heading Machine Market are armin Ltd., CatEye Co., Ltd., Wahoo Fitness, Sigma Sport, Bryton Inc., Lezyne, Polar Electro Oy, Bontrager (Trek Bicycle Corporation), Stages Cycling LLC, Pioneer Corporation, SRM GmbH, Magene Technology Co., Ltd., Giant Manufacturing Co., Ltd., Topeak Inc., Mio Technology (Navman Group). The cold heading process is seeing an increase in demand owing to the production of intricate auto parts, bolts, nuts and other industrial components that require tight tolerances and complex geometries. Some of the key players are adopting strategies like mergers, acquisitions and new product development to strengthen their market position and expand globally.

The automotive industry is exhibiting high demand for cold headed parts such as bolts, nuts, differential gears and transmission components owing to the need for durable, lightweight parts in vehicles. Countries like China, India, Brazil, Mexico, Czech Republic, Poland and Germany are witnessing significant expansions in their automotive manufacturing capacities which is driving the demand for cold heading machines. Global original equipment manufacturers are also outsourcing and offshoring their automotive component production to lower cost regions boosting the industrial machinery demand.

Market Drivers

One of the key drivers for the Cold Heading Machine Market Size.is the growing fastener industry. Cold heading is widely used for manufacturing bolts, nuts, screws and other threaded fastener types due to advantages like net-shape production without need for secondary operations. The construction and infrastructure development activities across major developing economies are driving the demand for fastening components. Also, the automotive, industrial machinery and equipment manufacturing industries have high dependence on bolts and screws which is propelling the cold heading volumes and machine requirements globally.

Impact of geopolitical situation on Cold Heading Machine Market growth

The Cold Heading Machine Market Size.is witnessing fluctuations due to changing geopolitical dynamics across major regions. The ongoing Russia-Ukraine war has disrupted global supply chains and manufacturing activities. Both Russia and Ukraine are major suppliers of raw materials used in Cold Heading Machine production. The conflict has led to an increase in prices of steel and other metals used by manufacturers. Moreover, export restrictions on Russian goods have created shortages in the market. Extended lockdowns in China due to its zero-COVID policy have also impacted the growth prospects of the Cold Heading Machine market. The intermittent halts in industrial production causes delays in shipments and completion of existing orders.

Going forward, for sustained growth manufacturers must develop alternate sourcing strategies and diversify supplier networks to mitigate concentration risks from specific regions. They need to invest more in automation and advanced technologies to improve productivity during uncertain times. Co-operation between regional trading blocs can facilitate cross-border movement of goods and ensure continuity of supply. Governments must implement favorable trade policies and incentives to attract investments that boost local manufacturing capabilities over the long term.

Geographically, Western Europe currently holds the largest share in the Cold Heading Machine market owing to extensive usage across automotive, fastener and medical device industries. Asia Pacific is recognized as the fastest growing regional market propelled by Chinese manufacturers and presence of key global OEMs in countries like India. North America is rising steadily due to replacement demand from transportation sector and aerospace applications. Governments across Middle East Africa and Latin America are undertaking various initiatives to develop local cold forming clusters and attract MNCs, which bodes well for future expansion.

Geographical regions where Cold Heading Machine market is concentrated:

The Cold Heading Machine market has strong concentration in Western European region in terms of value. Countries like Germany, Italy, UK and France have a well-established automotive components manufacturing base which drives the adoption of Cold Heading Machines for high volume production applications. German brands like Armin and SACMA enjoy global leadership in various machine type categories. Italian firms have vast experience in customized solutions for stringent medical industry standards. European automotive OEMs have integrated production networks within the region which propels localized procurement. Overall about 35-40% of the worldwide Cold Heading Machine market value is accounted for by Western Europe currently owing to advanced production capabilities and concentrated demand centers.

Fastest growing region for Cold Heading Machine market:

Asia Pacific region is poised to witness the fastest growth in the Cold Heading Machine market over the forecast period. China, with its colossal industrial manufacturing sector spanning automotive, electronics, tools etc offers lucrative opportunities. Chinese manufacturers are rapidly automating operations to meet volumes and opting for advanced Cold Heading Machines. Countries like India are prioritizing development of metal forming industries under Make in India. Indian automotive domestic market is expanding coupled with engineering exports growth. Presence of Japanese multinationals have spawned supplier ecosystems. Southeast Asian nations have emerged as automotive/EV hubs attracting investments. Government schemes in the region aim to enhance competitiveness through technology adoption. Overall increased investments, evolving supply chains and rising consumption will propel the Asia Pacific Cold Heading Machine market towards strongest gains through 2031.

Get More Insights On Cold Heading Machine Market