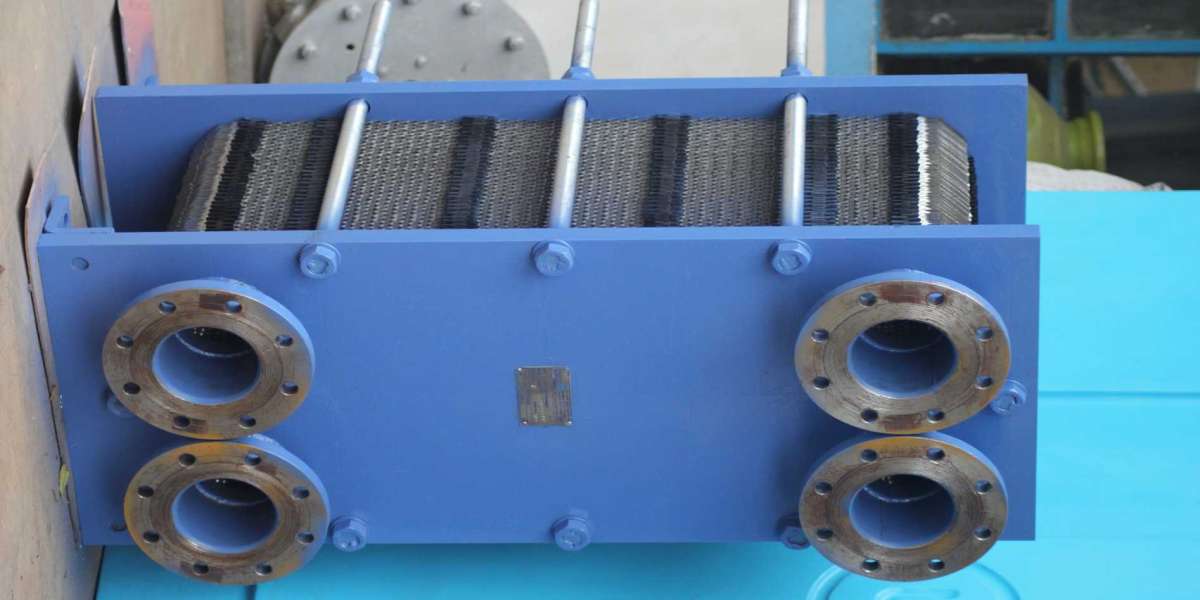

What Is a Plate Heat Exchanger?

A plate heat exchanger (PHE) is a device that transfers heat between two fluids (like water, oil, or gas) without mixing them. It works using thin, corrugated metal plates that create channels for the fluids to flow through. These plates separate the hot fluid from the cold fluid but allow heat to pass through efficiently.

Plate heat exchangers are commonly used in systems that require fast, compact, and efficient heat exchange.

How Does a Plate Heat Exchanger Work?

The working principle of a plate heat exchanger is straightforward and efficient. Here’s how it works step by step:

- Fluid Inlet: Two fluids—one hot and one cold—enter the heat exchanger through separate inlet ports.

- Flow Between Plates: The fluids flow through alternate channels between the plates. The hot fluid and cold fluid are separated by the metal plates, ensuring they never mix.

- Heat Transfer: Heat from the hot fluid passes through the thin plates and transfers to the cooler fluid. This happens because metal conducts heat quickly.

- Fluid Outlet: Once the heat transfer is complete, the two fluids exit the heat exchanger through separate outlet ports.

The unique design of the plates (with grooves or ridges) increases turbulence in the fluids, improving the rate of heat transfer.

Key Components of a Plate Heat Exchanger

Plate heat exchangers are made up of several simple parts:

- Plates: Thin sheets of metal (stainless steel or titanium) with grooves that enhance heat transfer.

- Gaskets: Rubber-like seals that prevent the two fluids from mixing and guide the flow.

- Frame: The outer casing that holds the plates and keeps them secure.

- Inlet and Outlet Ports: Openings for the two fluids to enter and exit the heat exchanger.

The plates are the heart of the heat exchanger, as they provide the large surface area needed for efficient heat transfer.

Types of Plate Heat Exchangers

There are different types of plate heat exchangers, each designed for specific uses. Let’s look at the most common ones:

1. Gasketed Plate Heat Exchangers:

- Plates are held together with gaskets, which can be removed for cleaning or maintenance.

- Uses: HVAC systems, food and beverage processes, and cooling systems.

2. Brazed Plate Heat Exchangers:

- Plates are permanently brazed together, creating a leak-proof and compact unit.

- Uses: Refrigeration, high-pressure systems, and domestic heating.

3. Welded Plate Heat Exchangers:

- Plates are welded instead of using gaskets, making them strong and durable.

- Uses: Chemical processes and systems handling aggressive or corrosive fluids.

4. Free-Flow Plate Heat Exchangers:

- Designed for fluids with particles or high viscosity to prevent clogging.

- Uses: Paper and pulp industries, and wastewater treatment systems.

Each type has its advantages and is chosen based on the specific requirements of the application.

Advantages of Plate Heat Exchangers

Plate heat exchangers are widely used because of their many benefits:

High Efficiency:

The large surface area of the plates ensures fast and efficient heat transfer.Compact Design:

PHEs take up much less space than traditional heat exchangers like shell-and-tube systems.Flexibility:

You can increase or decrease the number of plates to meet changing heat transfer needs.Easy Maintenance:

Gasketed models can be disassembled for cleaning and inspection.Energy Savings:

PHEs reduce energy waste, making systems more cost-effective and environmentally friendly.Versatility:

They can handle various types of fluids, including high-temperature, corrosive, or viscous liquids.

Applications of Plate Heat Exchangers

Plate heat exchangers are used in many industries and systems due to their efficiency and adaptability. Some key applications include:

1. HVAC Systems:

- Used for heating, cooling, and ventilation in residential and commercial buildings.

- Recovers energy in ventilation systems to save costs.

2. Food and Beverage Industry:

- Essential for processes like pasteurization, cooling, and heating of milk, juices, and beer.

- Ensures hygiene and maintains product quality.

3. Power Generation:

- Cools lubricating oils and other systems in power plants.

- Improves energy efficiency by recovering waste heat.

4. Chemical Industry:

- Handles corrosive and high-temperature fluids in chemical manufacturing processes.

5. Marine Industry:

- Used for engine cooling systems on ships, where seawater is commonly used as the cooling medium.

6. Renewable Energy:

- Plays a role in solar heating systems and geothermal energy plants.

These examples highlight the versatility of plate heat exchangers across a range of industries.

How to Maintain a Plate Heat Exchanger

Regular maintenance is key to ensuring the longevity and efficiency of plate heat exchangers. Here are a few simple tips to follow:

Clean Regularly:

- Remove any scaling, fouling, or deposits from the plates to maintain heat transfer efficiency.

Inspect Gaskets:

- Check for worn or damaged gaskets and replace them as needed to avoid leaks.

Check for Corrosion:

- Inspect the plates for corrosion, cracks, or warping. Damaged plates should be replaced immediately.

Monitor Operating Conditions:

- Ensure that the temperature and pressure of the fluids remain within the recommended limits.

Schedule Professional Servicing:

- Engage professional technicians for regular inspections and deep cleaning to identify potential problems early.

Proper maintenance will not only extend the life of the heat exchanger but also ensure optimal performance and energy efficiency.

Why Choose Plate Heat Exchangers?

Plate heat exchangers are a smart choice for industries and systems where efficient heat transfer is essential. Their compact size, high performance, and cost-effectiveness make them the preferred option over older technologies. Whether you need a system for heating, cooling, or recovering energy, PHEs offer:

- Faster heat transfer rates

- Flexible design for scaling up or down

- Lower energy costs

- Simple cleaning and maintenance

Conclusion

Plate heat exchangers are simple, efficient, and versatile devices that play a crucial role in heat transfer systems across industries. From HVAC systems to food processing and renewable energy plants, PHEs offer unmatched benefits in terms of performance, space savings, and cost efficiency.

Understanding the basics of how plate heat exchangers work, their types, and how to maintain them will help you get the most out of these devices. Whether for industrial use or everyday applications, plate heat exchangers are the perfect solution for modern energy-efficient systems.