Road construction is one of the fundamental pillars of infrastructure development worldwide. The challenges faced in constructing durable, cost-effective, and environmentally sustainable roads have led to the growing adoption of geosynthetics in modern construction practices. Among the various geosynthetic materials, geonets have emerged as an effective solution, particularly for improving the stability, drainage, and longevity of road infrastructure. Geonet geosynthetics in India have gained significant popularity due to their high-performance features and the increasing demand for efficient, sustainable road construction techniques.

What Are Geonets?

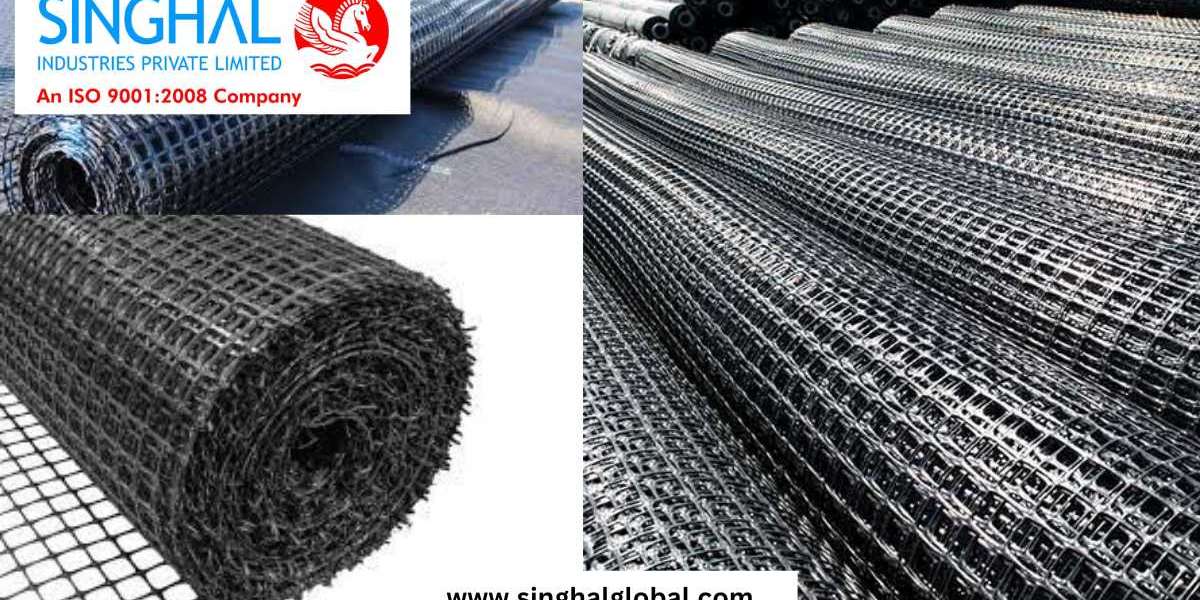

Geonets are synthetic polymeric materials designed to provide a stable foundation for roads, pavements, and other infrastructure projects. They consist of a network of interconnected ribs that form a three-dimensional open grid, which is used for reinforcement and drainage purposes. Geonets are often made from high-density polyethylene (HDPE) or polypropylene (PP), both of which are known for their durability and resistance to environmental factors.

In road construction, geonets are primarily used to improve drainage, stabilize the soil, and prevent the movement of the underlying subgrade. The open mesh structure of geonets allows for the efficient movement of water, preventing water accumulation that could lead to erosion or weakening of the roadbed. Additionally, geonets help distribute loads more evenly across the roadbed, enhancing the strength and durability of the road.

Benefits of Geonets in Road Construction

1. Improved Drainage: Geonets are primarily used for drainage improvement in road construction. The open mesh structure facilitates the rapid passage of water, preventing water from accumulating under the road surface. This is especially important in regions where heavy rainfall or waterlogging could weaken the roadbed. By reducing water accumulation, geonets help in maintaining the structural integrity of the road over time.

2. Soil Stabilization: In areas with weak or expansive soil, geonets provide an excellent solution for stabilizing the subgrade. When placed over the soil, geonets help distribute loads more evenly, preventing soil movement and subsidence. This improves the load-bearing capacity of the road and reduces the risk of deformation or cracking.

3. Cost-Effective Solution: Geonets are a cost-effective solution for improving the performance of roads. Compared to traditional methods like stone or concrete-based solutions, geonets are less expensive to install and maintain. Their ability to improve drainage and soil stabilization reduces the need for costly repairs and maintenance in the future, making them a smart investment for long-term infrastructure projects.

4. Environmentally Sustainable: Geonets are made from durable, long-lasting materials such as HDPE or PP, which are resistant to environmental factors like UV radiation, moisture, and chemicals. Their use reduces the need for frequent maintenance or replacement, leading to a reduction in the consumption of resources. Additionally, geonets help in managing stormwater runoff and erosion, contributing to environmental sustainability.

5. Enhanced Road Durability: The incorporation of geonets in road construction significantly extends the lifespan of the road. By preventing water damage and improving the load distribution, geonets help in minimizing cracks, rutting, and other forms of pavement distress. This ultimately leads to a smoother, safer, and longer-lasting road surface.

Applications of Geonets in Road Construction

1. Pavement Reinforcement: Geonets are used to reinforce road pavements and prevent cracking or deformation caused by the movement of the underlying soil. In areas where the subgrade is weak or unstable, geonets help distribute the loads more evenly, enhancing the overall strength of the pavement.

2. Subgrade Stabilization: In road construction projects where the subgrade consists of weak or expansive soils, geonets are placed between the soil layers to improve stability. The interlocking structure of geonets prevents the soil from shifting and helps to maintain the integrity of the road foundation.

3. Erosion Control: Geonets play a crucial role in erosion control along roads, especially in areas prone to heavy rainfall or flooding. By providing a stable surface and promoting effective water drainage, geonets help prevent the erosion of the roadbed and surrounding soil, reducing the risk of road damage and the need for costly repairs.

4. Drainage Systems: Geonets are commonly used in the construction of drainage systems along roads. They are placed in the base of the drainage channels or underneath the road surface to facilitate the smooth flow of water, preventing waterlogging and improving the overall drainage performance.

Geonet Geosynthetics in India

India, with its vast and diverse landscape, faces unique challenges in road construction, particularly due to varying soil conditions and extreme weather patterns. The use of geonet geosynthetics in India has grown significantly as a result of these challenges. With frequent monsoons, erosion-prone areas, and weak subgrades, geonets provide a reliable solution for improving drainage, stabilizing soil, and enhancing the longevity of roads. Geonet manufacturers in India are meeting the growing demand for these products, offering innovative solutions that cater to the specific requirements of Indian infrastructure projects.

Geosynthetics products manufacturers in India are working with various construction companies to supply high-quality geonets tailored to Indian road construction needs. These manufacturers ensure that the products meet international standards while also taking into account the local conditions, such as high rainfall, soil instability, and the heavy traffic load typical of Indian roads.

Geonets in Road Construction: Price and Market Trends

The cost of geonets in road construction depends on several factors, such as the material used, thickness, and the scope of the project. However, the price of geonets remains relatively affordable when compared to traditional methods of reinforcement and drainage. The Geosynthetics products manufacturers in India have made geonets more accessible, contributing to the growing adoption of these materials in road projects across the country.

The market for geonets in India is expected to expand further as the country continues to invest in infrastructure development. Government initiatives, such as the Bharatmala Pariyojana (National Highway Development Project), are driving the demand for geosynthetics in road construction. As road construction projects increase, so does the need for innovative and cost-effective solutions like geonets to ensure the durability and safety of roads.

FAQs

1. What is the primary function of geonets in road construction?

Geonets primarily serve two functions in road construction: improving drainage and stabilizing the subgrade. The open mesh structure of geonets allows for water to flow freely, preventing waterlogging and erosion, while also distributing loads more evenly to stabilize the underlying soil.

2. How do geonets help in soil stabilization?

Geonets improve soil stabilization by distributing the load over a larger area, reducing the chances of soil movement or subsidence. They are particularly effective in stabilizing weak or expansive soils that could otherwise lead to road deformation or cracking.

3. Can geonets be used in other applications besides road construction?

Yes, geonets can be used in various applications beyond road construction, including railway track stabilization, landfills, drainage systems, and even in the construction of embankments and slopes. Their versatility makes them suitable for numerous geotechnical projects.