Introduction

In the world of heavy machinery, engines are the heart of operations, and proper lubrication is its lifeblood. Diesel engine oils and greases play distinct yet complementary roles in ensuring the smooth functioning and longevity of industrial equipment. This article delves into the importance of these lubricants and how they contribute to machinery performance.

Understanding Diesel Engine Oils

- What Are Diesel Engine Oils?

Diesel engine oils are specialized lubricants formulated for diesel-powered engines. These oils handle high temperatures and heavy loads, making them essential for maintaining engine efficiency. - Functions of Diesel Engine Oils:

- Friction Reduction: Ensures minimal wear and tear between moving parts.

- Heat Dissipation: Keeps the engine cool during prolonged operation.

- Contaminant Control: Prevents sludge, soot, and deposits from accumulating.

- Corrosion Protection: Shields engine components from rust and oxidation.

- Additives in Diesel Engine Oils:

Diesel engine oils often include additives like detergents, dispersants, and anti-wear agents to enhance their performance and provide long-lasting protection.

The Role of Greases in Maintenance

- What Are Greases?

Greases are semi-solid lubricants designed for parts where liquid oils are impractical. Their thick consistency allows them to stay in place, even under extreme pressure or in exposed conditions. - Functions of Greases:

- Protect bearings and joints from wear.

- Seal against contaminants like dust and water.

- Provide long-lasting lubrication for low-speed, high-load components.

- Types of Greases:

Greases are often categorized by their base (mineral or synthetic) and thickener type (e.g., lithium or calcium). Each type is suited for specific applications and environments.

How Diesel Engine Oils and Greases Work Together

- Complementary Roles:

While diesel engine oils primarily handle the dynamic lubrication of engine internals, greases protect components like bearings, hinges, and joints. Together, they provide comprehensive protection. - Industrial Applications:

- In construction, diesel oils keep engines running smoothly, while greases maintain the stability of tracks and joints in bulldozers and excavators.

- In transportation, greases protect suspension systems, while diesel oils ensure engine reliability in trucks and buses.

- Reducing Downtime and Costs:

By using high-quality Diesel engine oils and greases, industries can prevent equipment breakdowns, extend machinery life, and reduce maintenance costs.

Choosing the Right Lubricants

- Key Considerations:

- Match the lubricant to the machine's requirements.

- Ensure compatibility with environmental conditions, such as temperature and moisture.

- Importance of Regular Maintenance:

Proper scheduling of oil changes and grease application ensures optimal performance and prevents unforeseen failures.

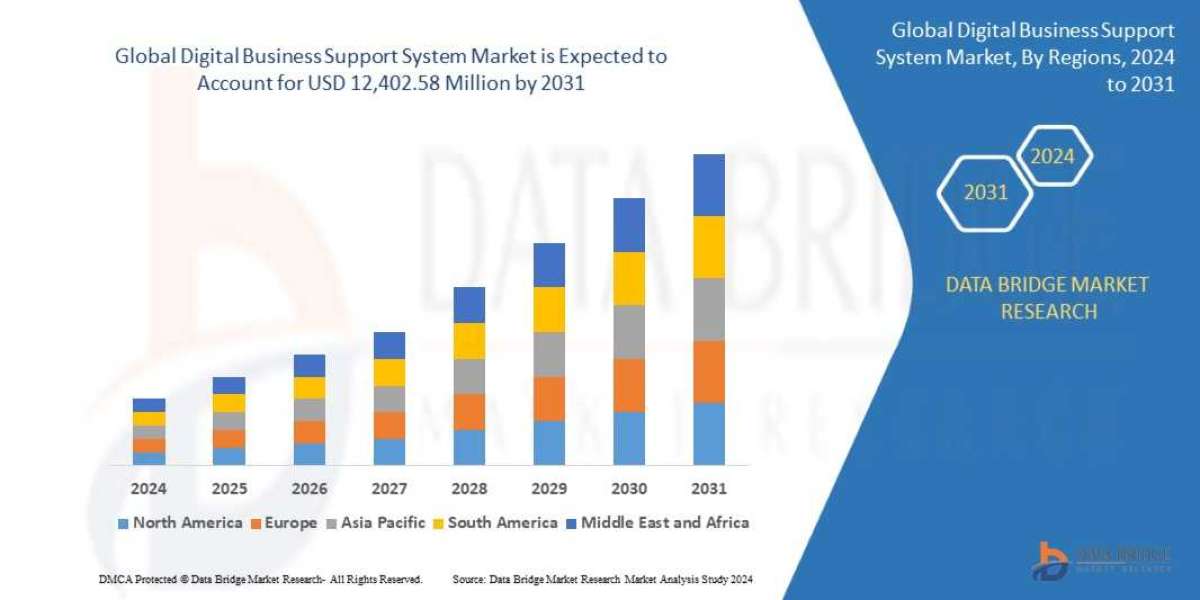

Future Trends in Diesel Engine Oils and Greases

The development of bio-based and synthetic lubricants is paving the way for eco-friendly options. Smart lubricants with sensors for real-time monitoring are also gaining traction, offering enhanced efficiency and safety.

Conclusion

Diesel engine oils and greases are indispensable in industrial and automotive applications. Understanding their unique roles and benefits allows businesses to optimize machinery performance, reduce costs, and enhance operational efficiency.