Among the many materials used in these systems, CPVC fittings have emerged as a preferred choice across commercial, residential, and industrial sectors. Known for their chemical resistance, ease of installation, and longevity, CPVC (Chlorinated Polyvinyl Chloride) fittings have transformed the way fire sprinkler systems are designed and maintained.

Why CPVC Fittings Matter in Fire Protection?

CPVC fittings are specially designed for fire suppression applications. These thermoplastic connectors are used to join CPVC pipes in fire sprinkler systems. Unlike traditional metal alternatives, CPVC offers numerous advantages that align with the demands of modern fire protection.

Some of the key benefits include:

- Corrosion Resistance: CPVC fittings do not rust or corrode over time, ensuring the integrity of the fire system remains intact for years.

- Lightweight Easy Handling: Compared to steel or copper, CPVC fittings are significantly lighter, making them easier and quicker to install, especially in overhead applications.

- Cost-Effective: With minimal maintenance and a long service life, CPVC reduces both labor and long-term operational costs.

- Smooth Interior Surfaces: This ensures lower friction loss, improving hydraulic performance within the sprinkler system.

- Approved for Fire Safety Standards: Reputable CPVC fittings are UL listed and FM approved, meeting international fire safety regulations.

Applications of CPVC Fittings in Fire Sprinkler Systems

CPVC fittings are used in both wet pipe and pre-action fire sprinkler systems. These fittings can be found in a wide array of environments, including:

- Residential homes and apartment buildings

- Hospitals and healthcare facilities

- Educational institutions

- Office buildings

- Warehouses and industrial spaces

Their adaptability and reliability make them a versatile solution for various occupancy types, especially where corrosion concerns make metal systems less ideal.

Types of CPVC Fittings Available

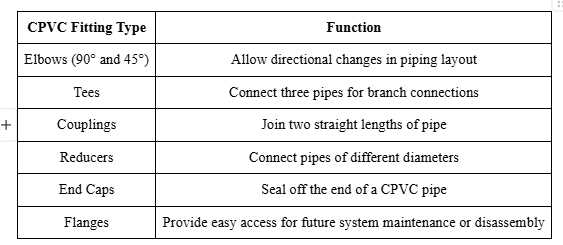

Fire Protection Parts offers a full range of CPVC fittings to support a wide variety of configurations and piping needs. Some of the most common types include:

All fittings are precision-molded to ensure a tight, leak-free fit that supports long-term system reliability.

Installation Best Practices

Though CPVC fittings are simple to install, adhering to manufacturer guidelines is essential. Proper solvent cementing and curing times must be observed to maintain joint strength. Installers must also ensure compatibility between the pipe and fitting brands to avoid performance issues. Additionally, systems must be pressure-tested according to applicable codes before being put into operation.

Training and certification for CPVC installation are strongly recommended and often required by local codes or insurers. Fire Protection Parts supports contractors by providing access to reliable fittings and technical guidance.

CPVC vs. Metal: Why the Shift?

Traditional systems made from galvanized steel or copper have served the fire protection industry for decades. However, CPVC has gained prominence due to:

- Lower installation costs

- Faster deployment

- Resistance to scale and corrosion

- Better flow rates over time

The non-metallic nature of CPVC also reduces the risk of contamination and internal buildup, especially in hard water environments.

Summing It Up

CPVC fittings have become a mainstay in the fire protection industry, and for good reason. Their durability, ease of use, and compliance with global safety standards make them an excellent choice for both new installations and retrofits. As fire safety standards evolve, using high-quality CPVC fittings from trusted suppliers like Fire Protection Parts ensures your fire sprinkler system will operate reliably when it matters most.

Whether you’re designing a fire system for a residential high-rise or upgrading a commercial warehouse, CPVC fittings deliver performance you can trust.

So, explore our full range of fire safety components, including CPVC fittings and hose equipment, at Fire Protection Parts. Let us help you build safer systems, one fitting at a time.