The global resin market is set to experience robust growth, fueled by increasing demand across a wide range of industries, including automotive, construction, electronics, and packaging. Resins are crucial materials in the production of plastics, coatings, adhesives, and composites, offering versatility, strength, and durability. As industries continue to innovate and expand, the resin market is expected to witness significant advancements, driven by the need for high-performance and sustainable materials.

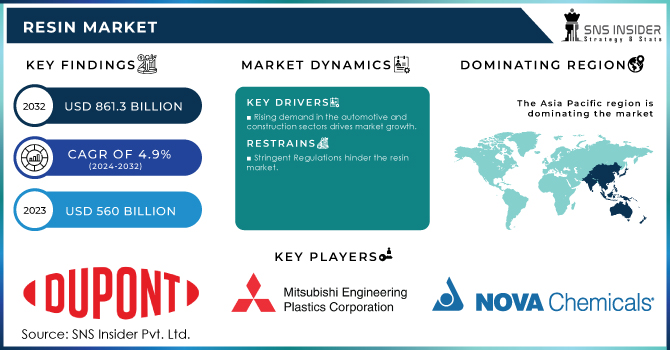

The Resin Market size was valued at USD 560 Billion in 2023. It is expected to grow to USD 861.3 Billion by 2032 and grow at a CAGR of 4.9% over the forecast period of 2024-2032.

Key Market Drivers:

- Growth in Automotive Industry: Resins are integral to the production of automotive parts, particularly for lightweighting, improving fuel efficiency, and enhancing vehicle performance. The shift toward electric vehicles (EVs) and the increasing demand for lightweight, durable components are driving the growth of the resin market within the automotive sector. Resins are used in manufacturing parts such as bumpers, dashboards, and body panels, contributing to the overall demand for composite materials.

- Expansion of the Construction Sector: The construction industry’s increasing reliance on resins for applications like coatings, adhesives, and sealants is a significant driver for the market. Resins play a key role in enhancing the durability and aesthetic appeal of materials used in building and infrastructure projects. As urbanization and infrastructure development continue to grow globally, the demand for resins in construction applications is expected to rise.

- Electronics and Electrical Industry Growth: Resins are crucial in the electronics industry, where they are used in manufacturing circuit boards, components, and electrical insulation materials. The rapid growth of consumer electronics, including smartphones, computers, and electric vehicles, is boosting the demand for advanced resins that offer improved performance and efficiency.

- Demand for Sustainable Packaging Solutions: Resins are widely used in the production of packaging materials due to their versatility and ability to be molded into various shapes and forms. The increasing demand for eco-friendly and sustainable packaging solutions, driven by consumer preferences and regulatory pressures, is fueling the growth of bio-based and recyclable resins.

Key Applications:

- Automotive Manufacturing:

- Resins are widely used in automotive applications to create lightweight, durable components. The push for more energy-efficient vehicles, including electric and hybrid models, is driving innovation in resin materials for automotive parts.

- Construction and Building Materials:

- In the construction industry, resins are used in adhesives, sealants, and coatings that enhance the performance, longevity, and appearance of buildings and infrastructure. The growing need for durable and weather-resistant construction materials is boosting resin demand.

- Electronics and Electrical Components:

- Resins are crucial in electronics for their ability to provide electrical insulation, protection from heat, and structural stability. As the demand for high-tech electronics continues to grow, resin usage in these products is expected to rise.

- Packaging Industry:

- Resins play a pivotal role in producing packaging materials such as films, containers, and bottles. The rise of sustainable packaging solutions has spurred the development of bio-based and recyclable resins, aligning with environmental goals.

Market Trends:

- Sustainability and Green Chemistry: As the focus on environmental sustainability intensifies, the demand for bio-based and recyclable resins is increasing. Manufacturers are investing in developing more sustainable resin options, which are expected to shape the future of the market as industries strive to reduce their carbon footprint.

- Technological Advancements in Resin Production: Innovations in resin manufacturing, including the development of high-performance and cost-effective materials, are contributing to the market’s growth. Advances in resin formulations, such as improved thermal stability, UV resistance, and durability, are expanding the range of applications across industries.

- Emerging Markets and Infrastructure Development: The rapid industrialization and urbanization in emerging economies, particularly in regions such as Asia-Pacific, are creating new opportunities for resin demand. Infrastructure development, growing construction projects, and increased automotive production in these regions are driving resin consumption.

Key Players

- Dupont

- Mitsubishi Engineering-Plastics Corporation

- Nova Chemicals

- Arkema

- BASF SE

- LyondellBasell

- INEOS Holdings Ltd.

- Qenos

- Hexion

- Invista

- Dow Chemical Company

- SABIC

- Sumitomo Chemical

- ExxonMobil Chemical

- Celanese Corporation

- Solvay

- Evonik Industries

- Teijin Limited

- Toray Industries

- Formosa Plastics Corporation

Conclusion:

The global resin market is poised for strong growth, driven by its critical role in automotive, construction, electronics, and packaging industries. As industries continue to prioritize sustainability, technological advancements, and high-performance materials, the demand for resins is expected to remain robust. With continued innovation in production processes and a growing emphasis on eco-friendly solutions, the resin market is set to meet the challenges of modern industries and contribute to the development of sustainable products.

For more details @ https://www.snsinsider.com/reports/resin-market-3695

Contact Us:

Akash Anand – Head of Business Development Strategy

info@snsinsider.com

Phone: +1-415-230-0044 (US)