Vacuum coating machines are vital for depositing thin, uniform coatings on various materials in a controlled vacuum environment. The process involves vaporizing the coating material and allowing it to condense on the substrate, forming a protective or functional layer. These machines are critical in industries like electronics for creating components such as semiconductors, displays, and solar panels. As demand for advanced materials and efficient manufacturing processes rises, vacuum coating technology has evolved to include more precise control, better material utilization, and greater environmental sustainability. The market is expanding rapidly as industries seek cost-effective and high-performance coating solutions.

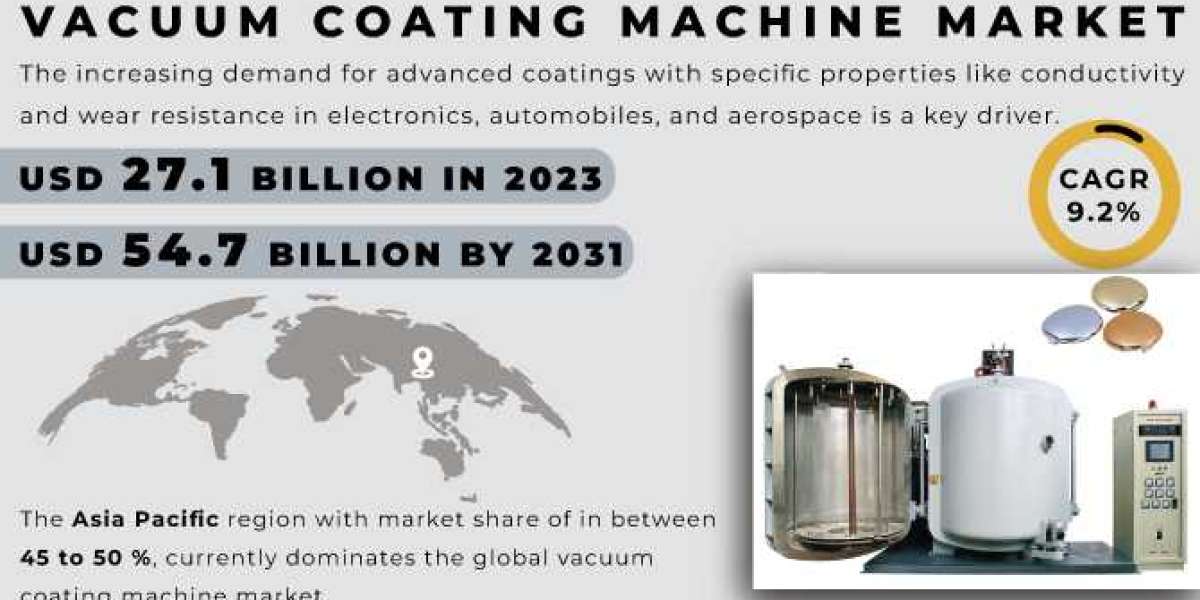

The Vacuum Coating Machine Market Size was valued at USD 27.1billion in 2023 and is expected to reach USD 54.7 billion by 2031 and grow at a CAGR of 9.2 % over the forecast period 2024-2031.

Drivers:

- Growing demand for advanced materials:Industries are increasingly adopting vacuum coating for its ability to apply high-quality coatings.

- Technological advancements:Innovations in coating materials, equipment, and processes are driving market growth.

- Expanding electronics and automotive industries:Both sectors require vacuum coating for producing durable, high-performance components.

- Rising environmental concerns:Vacuum coating processes are more environmentally friendly compared to traditional coating methods.

Future Scope:

- Increased adoption of vacuum coating in the production of flexible and wearable electronics.

- Growth in solar panel manufacturing due to the need for efficient coatings in energy conversion.

- Development of more energy-efficient and environmentally sustainable vacuum coating machines.

- Expansion of vacuum coating applications in the aerospace and defense sectors.

- Integration with smart manufacturing technologies and automation for improved efficiency.

Emerging Trends:

- Use of eco-friendly coatingsthat reduce harmful emissions and improve sustainability.

- Integration of AI and machine learningfor real-time process optimization and quality control.

- Advancements in PVD (Physical Vapor Deposition) and CVD (Chemical Vapor Deposition)for more precise coating techniques.

- Growth in multi-functional coatingsfor applications like anti-reflective, anti-scratch, and corrosion resistance.

- Use of vacuum coating in 3D printingto enhance the surface properties of printed parts.

Conclusion:

The vacuum coating machine market is experiencing significant growth driven by advancements in technology, increased demand from various industries, and a focus on sustainability. As applications continue to expand in fields like electronics, automotive, and solar energy, the industry will see continued innovations in coating materials, machine efficiency, and process control. With the integration of smart manufacturing and eco-friendly practices, the future of vacuum coating machines is promising, offering new opportunities for high-performance, cost-effective solutions.

Read Full Report @https://www.snsinsider.com/reports/vacuum-coating-Equipment-market-1188

Contact Us:

Akash Anand – Head of Business Development Strategy

info@snsinsider.com

Phone: +1-415-230-0044 (US) | +91-7798602273 (IND)