The electric vehicle (EV) adhesives market is experiencing significant growth and transformation, driven by several key trends that are shaping the future of electric mobility. As the automotive industry shifts towards electrification, adhesives are playing an increasingly crucial role in enhancing vehicle performance, safety, and sustainability. This article explores the top trends driving the electric vehicle adhesives market.

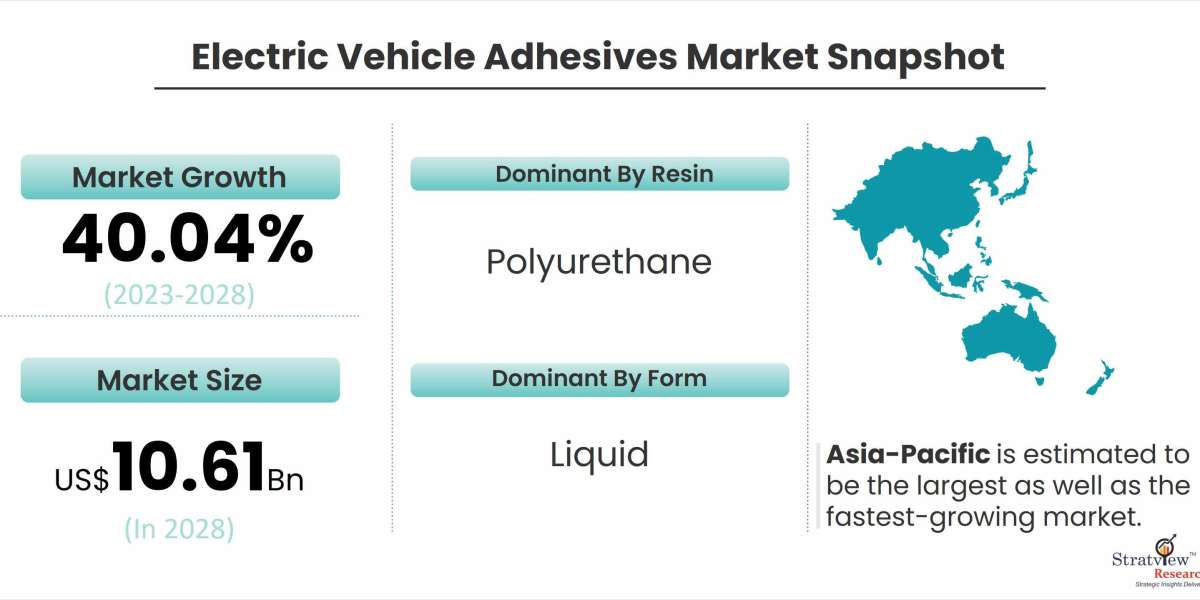

According to Stratview Research, the electric vehicle adhesives market was estimated at USD 1.38 billion in 2022 and is likely to grow at a CAGR of 40.04% during 2023-2028 to reach USD 10.61 billion in 2028.

- Lightweighting Initiatives

One of the primary trends in the electric vehicle adhesives market is lightweighting. Adhesives enable the bonding of lightweight materials such as aluminum, composites, and high-strength steel, reducing the overall weight of electric vehicles. This trend is critical for improving energy efficiency and extending the driving range of EVs, which is a key factor in consumer adoption.

- Demand for High-Performance Adhesives

The demand for high-performance adhesives is on the rise in the electric vehicle industry. These adhesives offer superior bonding strength, durability, and resistance to temperature extremes, vibrations, and moisture. They are used in critical applications such as battery pack assembly, where reliability and safety are paramount.

- Increased Focus on Battery Pack Assembly

Battery pack assembly is a significant application area for adhesives in electric vehicles. Adhesives are used to bond battery cells together, ensuring a secure and compact arrangement while providing electrical insulation. This method not only reduces the weight of the battery pack but also simplifies assembly processes and enhances the safety and longevity of the battery system.

- Advancements in Thermal Management

Effective thermal management is crucial for the performance and longevity of electric vehicle components, particularly batteries and electric motors. Adhesives play a vital role in bonding heat sinks, thermal interface materials, and other components that dissipate heat, ensuring optimal thermal conductivity and heat dissipation.

- Sustainability and Environmental Regulations

Sustainability is becoming increasingly important in the electric vehicle adhesives market. Manufacturers are developing adhesives with reduced VOC emissions and environmental impact to meet stringent regulations. Additionally, adhesives contribute to the overall environmental footprint of electric vehicles by enabling the use of lightweight materials and improving energy efficiency.

- Integration of Advanced Sensors and Electronics

Electric vehicles incorporate a growing number of advanced sensors, electronics, and autonomous driving technologies. Adhesives are used to bond and seal these sensitive components, providing electrical insulation and protection from environmental factors. This trend is driving the demand for adhesives with high dielectric strength and reliability.

- Innovations in Hybrid Bonding Technologies

Hybrid bonding technologies, which combine mechanical fasteners with adhesives, are gaining traction in the electric vehicle industry. These technologies offer the benefits of both adhesive bonding and mechanical fastening, providing enhanced structural integrity, flexibility, and ease of assembly.

- Growth in Electric Vehicle Production

The rapid growth in electric vehicle production globally is a significant driver of the adhesives market. As automakers ramp up production to meet growing consumer demand and regulatory requirements, the demand for adhesives used in EV manufacturing is expected to increase substantially.

- Focus on NVH (Noise, Vibration, and Harshness) Reduction

Adhesives help dampen noise and reduce vibration inside electric vehicles, contributing to a quieter and more comfortable driving experience. By replacing mechanical fasteners, adhesives minimize the potential for squeaks and rattles, enhancing overall vehicle quality and customer satisfaction.

- Regional Expansion and Investments

Major adhesive manufacturers are expanding their production capacities and investing in research and development to meet the specific needs of the electric vehicle market. Regions such as Asia-Pacific and Europe are witnessing significant investments in electric vehicle manufacturing, driving the demand for advanced adhesive solutions.

Conclusion

In conclusion, the electric vehicle adhesives market is evolving rapidly, driven by trends such as lightweighting, high-performance requirements, battery pack assembly, thermal management, sustainability, advanced electronics integration, hybrid bonding technologies, electric vehicle production growth, NVH reduction, and regional expansion. These trends are reshaping the automotive industry and paving the way for more efficient, sustainable, and technologically advanced electric vehicles. Adhesive manufacturers and suppliers are well-positioned to capitalize on these opportunities by developing innovative solutions that meet the evolving needs of electric vehicle manufacturers and consumers alike.