The global Digital Textile Printing Inks Market is experiencing significant growth, driven by the increasing demand for customized, high-quality, and sustainable textile printing solutions. With advancements in digital printing technologies, the textile industry is rapidly shifting from conventional printing methods to eco-friendly, cost-efficient, and high-precision digital printing.

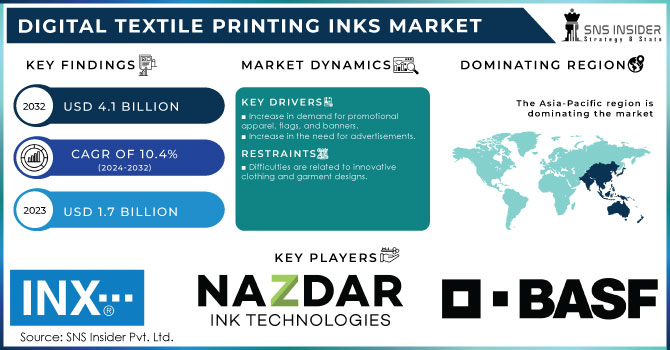

The Digital Textile Printing Inks Market size was USD 1.7 billion in 2023 and is expected to reach USD 4.1 billion by 2032 and grow at a CAGR of 9.6% over the forecast period of 2024-2032.

Key Growth Drivers:

- Rising Demand for Customization and On-Demand Printing

The growing popularity of personalized apparel, home décor, and fashion products is fueling demand for digital textile printing inks. Brands and designers are leveraging on-demand printing to reduce waste, optimize inventory, and cater to fast-changing consumer preferences.

- Shift Toward Sustainable and Eco-Friendly Printing Solutions

As sustainability becomes a key focus in the textile industry, the adoption of water-based, biodegradable, and low-VOC inks is accelerating. Digital textile printing reduces water and chemical consumption compared to traditional methods, making it an environmentally responsible choice for textile manufacturers.

- Expansion of the Fashion and Apparel Industry

With fast fashion and high-quality sportswear, activewear, and home textiles on the rise, digital printing offers superior color vibrancy, durability, and design flexibility. The e-commerce boom and the direct-to-garment (DTG) trend are further propelling market growth.

- Technological Advancements in Ink Formulations

Innovations in pigment-based, dye sublimation, reactive, and UV-curable inks are enhancing fabric compatibility, print longevity, and resistance to washing and fading. These advancements are expanding the scope of digital textile printing across multiple fabric types, including cotton, polyester, silk, and blends.

- Cost Efficiency and Faster Production Cycles

Compared to traditional screen printing, digital textile printing minimizes setup costs, reduces material waste, and allows for quicker turnaround times. This makes it an ideal solution for short-run production, prototyping, and high-mix, low-volume manufacturing.

Challenges and Opportunities

While the market faces challenges such as high initial investment costs, ink compatibility issues, and regulatory compliance, continued RD, advancements in nanotechnology, and the emergence of hybrid printing technologies are paving the way for cost-effective and high-performance ink solutions.

Key Players

- INX International Ink

- JK Group

- Nazdar Company

- BASF SE

- Dover Corporation

- DyStar Group

- Zhengzhou Hongsam Digital Science Technology Co., Ltd.

- Huntsman Corporation

- Kornit Digital Ltd.

- Sensient Technologies Corporation

- Sawgrass Technologies

- SPGPrints B.V.

- Zhejiang Lanyu Digital Technology Co. Ltd

- Sun Chemical

- Toyo Ink SC Holdings Co.

Conclusion

As industries embrace digital transformation and sustainability, the digital textile printing inks market is set for exponential growth. Companies investing in innovative ink formulations, eco-friendly solutions, and advanced printing technologies are well-positioned to capitalize on the future of textile printing.

For more details @ https://www.snsinsider.com/reports/digital-textile-printing-inks-market-1458

Contact Us:

Akash Anand – Head of Business Development Strategy

info@snsinsider.com

Phone: +1-415-230-0044 (US)