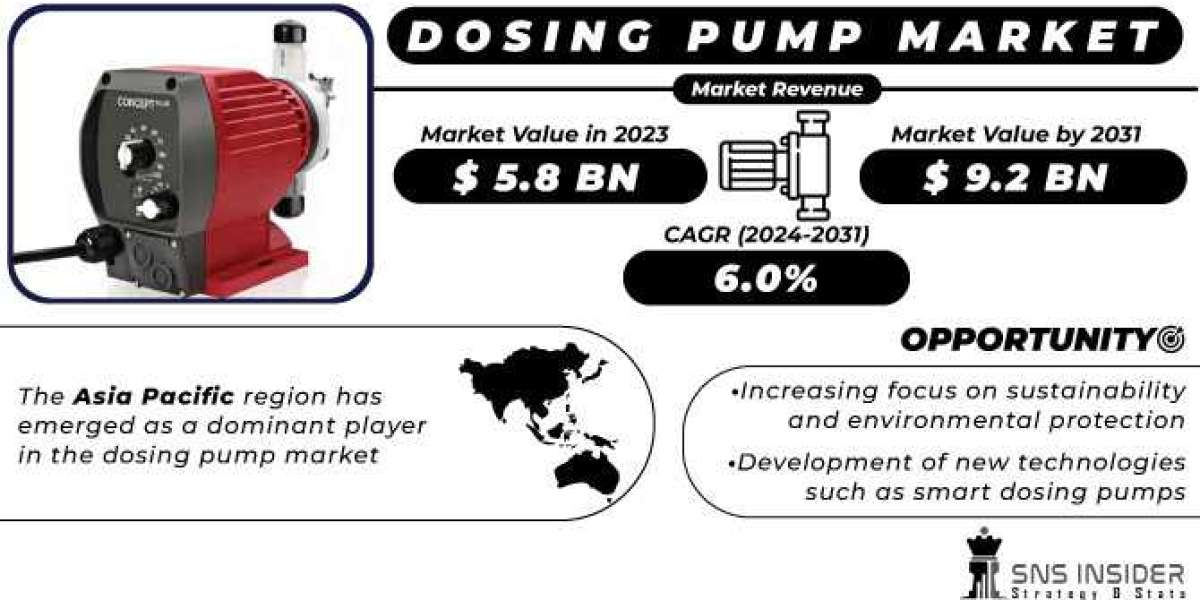

The Dosing Pump Market size was valued at USD 5.8 billion in 2023 and is expected to grow to USD 9.2 billion by 2031 with a growing CAGR of 6.0% over the forecast period of 2024–2031.

Market Overview

Dosing pumps play a vital role in various sectors by enabling accurate and controlled dispensing of fluids such as chemicals, acids, and other process substances. They are extensively used in water treatment plants, where they control pH levels and disinfect water, and in the pharmaceutical industry for precision dosing of ingredients in drug formulation. Increasing awareness of water quality, stringent environmental regulations, and the rise in demand for high-quality products across industries are fueling the market.

With advancements in digital and automated dosing systems, the market is shifting toward more intelligent solutions, which provide real-time monitoring, remote control, and enhanced safety features. These technological improvements are expected to drive adoption in industries that demand high precision and compliance with strict quality standards.

Key Market Drivers

- Increasing Demand for Water Treatment Solutions: Growing urbanization and industrialization have elevated the need for wastewater treatment, driving the demand for dosing pumps in municipal and industrial water treatment facilities.

- Stringent Regulatory Compliance: Stringent environmental regulations in sectors such as pharmaceuticals, chemicals, and water treatment mandate precise dosing solutions to control emissions and waste, supporting the growth of the dosing pump market.

- Technological Advancements in Automation: The integration of automation and smart technology in dosing pumps is enhancing operational accuracy, efficiency, and monitoring capabilities, making them highly desirable for critical applications.

- Growing Pharmaceutical and Food Industries: Dosing pumps are widely used in these industries for accurate measurement and controlled delivery of fluids, ensuring product consistency and quality.

- Emphasis on Energy-Efficient Solutions: Companies are focusing on energy-efficient dosing pumps that reduce operating costs and environmental impact, meeting both economic and ecological goals.

Market Segmentation

The Dosing Pump Market can be segmented by type, application, end-use industry, and region.

By Type

- Diaphragm Dosing Pumps: Known for their reliability and low maintenance, diaphragm dosing pumps are widely used in water treatment and chemical dosing applications.

- Piston Dosing Pumps: Offering high-pressure capabilities, piston dosing pumps are preferred for applications requiring precise dosing and high efficiency, such as in the oil gas sector.

- Peristaltic Dosing Pumps: These pumps are suitable for handling viscous fluids and slurries, commonly used in food beverage and pharmaceutical applications.

- Others: Includes specialized pumps designed for niche applications or customized solutions based on specific industry needs.

By Application

- Water Treatment: Dosing pumps play a crucial role in maintaining water quality by accurately dosing chemicals, pH balancers, and disinfectants.

- Chemical Processing: Dosing pumps are essential in chemical industries for controlled chemical mixing, ensuring process safety and efficiency.

- Pharmaceutical: In pharmaceuticals, dosing pumps ensure the precise addition of ingredients, critical for meeting regulatory standards and ensuring product efficacy.

- Oil Gas: Dosing pumps are used in oil gas for injecting chemicals, corrosion inhibitors, and other fluids, crucial for asset integrity and operational efficiency.

- Food Beverage: Dosing pumps help maintain consistent ingredient proportions, improving product quality and meeting health and safety regulations.

By End-Use Industry

- Municipal and Industrial Water Treatment

- Oil Gas

- Pharmaceutical

- Food Beverage

- Chemical and Petrochemical

- Agriculture

- Others

Regional Analysis

- North America: North America holds a substantial market share due to strict regulatory frameworks governing water and chemical management. Additionally, significant investment in automation across industries is propelling the demand for advanced dosing pumps in the region.

- Europe: Europe’s dosing pump market is driven by stringent environmental regulations, particularly in water treatment and chemical sectors. The growing focus on sustainability and the adoption of smart dosing systems are fostering market growth in this region.

- Asia-Pacific: Asia-Pacific is expected to witness the highest growth, fueled by rapid industrialization, urbanization, and an increasing need for water treatment in countries like China and India. Expanding pharmaceutical and food industries in the region also contribute to the demand for dosing pumps.

- Middle East Africa: In the Middle East Africa, the oil gas sector’s expansion and investments in water infrastructure are driving demand for dosing pumps. These regions also see an increasing focus on effective wastewater management.

- Latin America: Latin America is gradually adopting dosing pump technology across industries, with growing investments in water treatment and food beverage sectors supporting market growth.

Current Market Trends

- Increased Demand for Smart and Automated Dosing Solutions: The integration of IoT, AI, and remote monitoring features in dosing pumps allows real-time control and data analysis, enhancing operational efficiency and predictive maintenance.

- Focus on Sustainability and Energy Efficiency: Manufacturers are designing dosing pumps that consume less energy while providing high accuracy, catering to environmentally conscious industries.

- Customization of Dosing Pumps for Industry-Specific Applications: Companies are increasingly offering custom solutions to meet the specific needs of industries like pharmaceuticals, oil gas, and water treatment, making dosing pumps more adaptable to diverse requirements.

- Development of Compact and Portable Dosing Pumps: Compact and portable dosing pumps are gaining popularity for their ease of integration and use in smaller facilities or applications with space constraints.

- Adoption of Corrosion-Resistant Materials: To extend the longevity of dosing pumps in aggressive chemical environments, manufacturers are adopting corrosion-resistant materials, such as stainless steel and specialized coatings.

Read Complete Report Details of Dosing Pump Market: https://www.snsinsider.com/reports/dosing-pump-market-2824

About Us:

SNS Insider is a global leader in market research and consulting, shaping the future of the industry. Our mission is to empower clients with the insights they need to thrive in dynamic environments. Utilizing advanced methodologies such as surveys, video interviews, and focus groups, we provide up-to-date, accurate market intelligence and consumer insights, ensuring you make confident, informed decisions.

Contact Us:

Akash Anand — Head of Business Development Strategy

info@snsinsider.com

Phone: +1–415–230–0044 (US) | +91–7798602273 (IND)