In the rapidly advancing world of industrial infrastructure, electrical management is paramount. As systems become more complex, the demand for efficient, durable, and adaptable solutions grows. Among these solutions, perforated cable trays and control panels play a vital role in organizing and safeguarding electrical systems. Choosing the right manufacturer is a crucial decision for businesses, ensuring reliable and cost-effective outcomes.

If you’re looking for the best in the industry, JP Shine Electrical stands out as a trusted Perforated Cable Tray Manufacturer and Control Panel Manufacturer, providing top-quality products that meet global standards. Let’s dive deeper into why these components are indispensable and how JP Shine Electrical delivers excellence in this space.

What Are Perforated Cable Trays?

A perforated cable tray is a type of cable management system designed to support and organize electrical cables in industrial and commercial settings. These trays feature perforations (holes) that allow for better ventilation, reduced cable heating, and easy water drainage.

Key Benefits of Perforated Cable Trays:

- Durability: Made from materials like galvanized steel, stainless steel, or aluminum, perforated cable trays are highly durable and resistant to environmental factors.

- Ventilation: The perforations ensure proper airflow around cables, minimizing overheating risks.

- Ease of Maintenance: With visible cables, it’s easier to identify and repair faults.

- Customizable: These trays come in various sizes and can be tailored to specific project needs.

JP Shine Electrical, as a premier Perforated Cable Tray Manufacturer, offers robust solutions tailored to diverse industries. Their trays are built to last, ensuring optimal performance even in challenging environments.

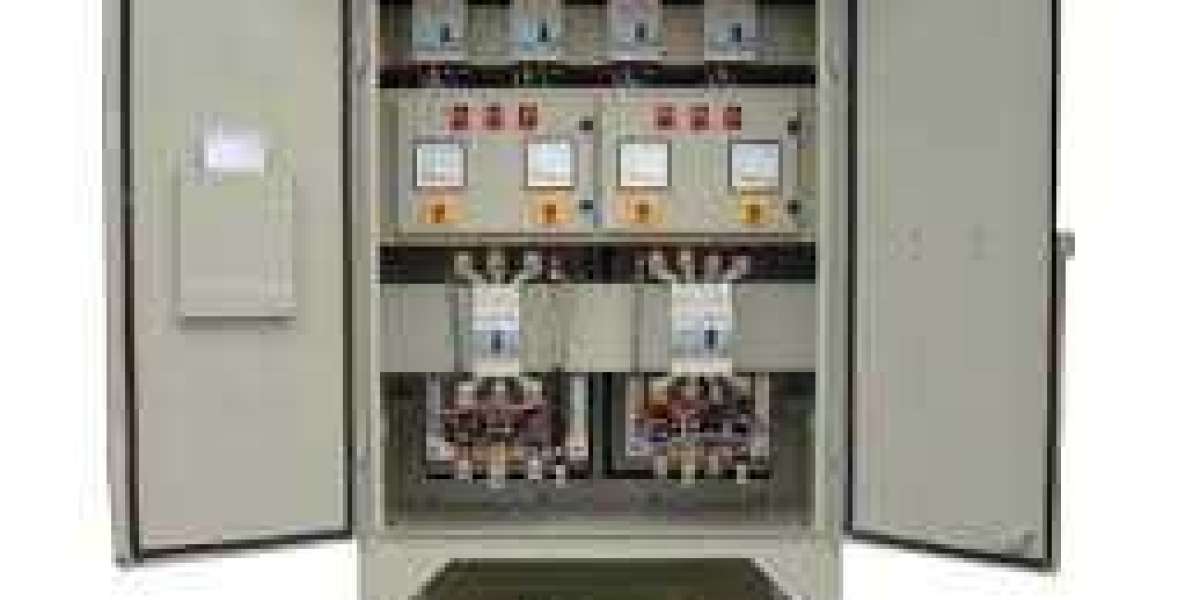

Understanding Control Panels

Control panels act as the central hub for monitoring and controlling machinery and processes in industries. A well-designed control panel ensures efficient operation, safety, and seamless integration of electrical systems.

Types of Control Panels:

- Power Control Panels: Manage and distribute electrical power to various machinery.

- Automation Panels: Used in automated systems to control and monitor processes.

- PLC Control Panels: Integrate programmable logic controllers for precise control of complex systems.

JP Shine Electrical, as a leading Control Panel Manufacturer, specializes in designing advanced panels that cater to diverse industrial requirements. Their panels are not only reliable but also compliant with international safety and quality standards.

Why Choose JP Shine Electrical?

When selecting a Perforated Cable Tray Manufacturer or a Control Panel Manufacturer, the focus should be on quality, customization, and after-sales support. Here’s why JP Shine Electrical is the ideal partner for your electrical infrastructure needs:

1. Commitment to Quality

JP Shine Electrical is renowned for delivering top-notch products crafted with precision. Their perforated cable trays are manufactured using premium-grade materials, ensuring durability and resistance to corrosion. Similarly, their control panels are engineered to provide reliable and uninterrupted performance.

2. Customization Options

Every industrial setup is unique, requiring tailored solutions. JP Shine Electrical excels at customizing products to fit specific project demands. Whether it’s a specialized cable tray size or a custom-configured control panel, they have you covered.

3. Competitive Pricing

High-quality doesn’t always mean high costs. JP Shine Electrical balances quality with affordability, ensuring businesses get value for their investment.

4. Exceptional After-Sales Support

From installation guidance to maintenance services, their team ensures a seamless experience for clients.

Applications of Perforated Cable Trays and Control Panels

Perforated Cable Trays

- Industrial Plants: Organizing and protecting cables in factories and manufacturing units.

- Commercial Buildings: Streamlining electrical wiring in offices and malls.

- Power Plants: Supporting cables in high-temperature and high-load environments.

Control Panels

- Automotive Industry: Managing robotic and automated production lines.

- Food Processing Units: Ensuring smooth operation of machinery.

- Renewable Energy: Controlling systems like solar power plants.

The versatility of products from JP Shine Electrical ensures they cater to a wide array of industries, providing reliable solutions that enhance efficiency and safety.

Tips for Choosing the Right Manufacturer

Selecting a manufacturer for perforated cable trays or control panels can be challenging. Here’s what to look for:

- Reputation: Research reviews and client testimonials.

- Certifications: Ensure compliance with industry standards like ISO or CE.

- Customization Capabilities: Opt for manufacturers who offer tailored solutions.

- Technical Support: A reliable after-sales team is a must.

With JP Shine Electrical, you can rest assured of ticking all these boxes. Their commitment to excellence and client satisfaction makes them a preferred choice.

Future Trends in Cable Trays and Control Panels

As technology evolves, so do the demands on infrastructure components:

- Smart Control Panels: Integration with IoT and AI for predictive maintenance and efficiency optimization.

- Sustainable Materials: Increased focus on eco-friendly manufacturing.

- Modular Designs: Enhanced flexibility for installations and upgrades.

JP Shine Electrical stays ahead of the curve, adopting innovative techniques and sustainable practices to deliver future-ready solutions.

Final Thoughts

In industrial and commercial setups, efficient cable management and control systems are essential for smooth operations. Investing in high-quality perforated cable trays and control panels ensures long-term reliability and safety.

When it comes to finding a trusted Perforated Cable Tray Manufacturer and Control Panel Manufacturer, look no further than JP Shine Electrical. Their commitment to quality, innovation, and customer satisfaction sets them apart as a leader in the industry.

Whether you’re setting up a new facility or upgrading an existing one, JP Shine Electrical offers the expertise and solutions you need. Contact them today to learn more about their offerings and take your electrical systems to the next level.