Die making is a crucial process in various industries, including manufacturing, engineering, and product design. A die is a specialized tool used to cut, shape, and form materials into desired shapes and sizes. The die making process involves creating a customized die that meets specific requirements and specifications. In this article, we will delve into the die making process, from concept to creation, and explore the various stages involved in producing a high-quality die.

Design and Conceptualization

The die making process begins with design and conceptualization. This stage involves creating a detailed design of the die, taking into account the material to be used, the desired shape and size, and the production requirements. The design team uses computer-aided design (CAD) software to create a digital model of the die, which is then reviewed and refined to ensure accuracy and precision. The design should also consider factors such as die life, maintenance, and potential modifications. A well-designed die is essential to ensure efficient production, reduce waste, and minimize costs.

Material Selection

Once the design is finalized, the next step is to select the appropriate material for the die. The choice of material depends on the application, the type of material to be formed, and the desired lifespan of the die. Common materials used for die making process include steel, aluminum, and copper. Steel is a popular choice due to its high strength, durability, and resistance to wear and tear. Aluminum is often used for dies that require high precision and intricate details, while copper is used for dies that require high thermal conductivity. The selected material is then procured and prepared for the next stage of the process.

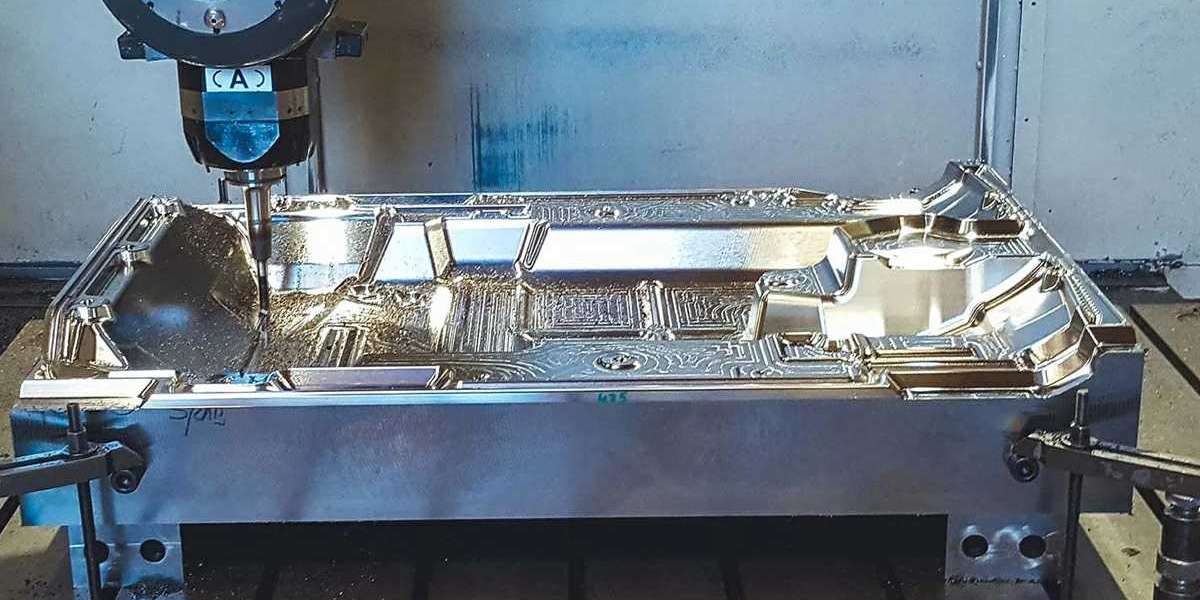

Machining and Fabrication

The machining and fabrication stage involves cutting, shaping, and forming the die material into the desired shape and size. This stage requires high-precision machinery, such as CNC machines, milling machines, and grinding machines. The die material is carefully machined to achieve the required tolerances and surface finish. The fabrication process may also involve additional operations, such as drilling, tapping, and welding. The die is then inspected for accuracy and quality to ensure that it meets the required specifications.

Heat Treatment and Finishing

Heat treatment and finishing are critical stages in the die making process. Heat treatment involves heating the die to a specific temperature to alter its microstructure and properties. This process can enhance the die's hardness, strength, and durability. The die is then cooled and inspected for any distortions or defects. The finishing stage involves applying a surface treatment to the die, such as polishing, coating, or plating. This enhances the die's performance, reduces wear and tear, and improves its overall lifespan.

Assembly and Testing

Once the die is complete, it is assembled and tested to ensure that it functions as intended. The die is mounted on a press or other machinery, and a series of tests are conducted to verify its performance. The tests may include checking the die's accuracy, precision, and durability. Any defects or issues are identified and addressed during this stage. The die is then certified and ready for use in production.

Maintenance and Repair

The die making process does not end with the creation of the die. Maintenance and repair are essential to ensure the die's longevity and performance. Regular maintenance involves cleaning, lubricating, and inspecting the die for wear and tear. Repairs may involve replacing worn-out parts, re-machining the die, or applying new surface treatments. Proper maintenance and repair can extend the die's lifespan, reduce downtime, and minimize production costs.

Conclusion

The die making process is a complex and intricate process that requires careful planning, precision engineering, and attention to detail. From design and conceptualization to assembly and testing, each stage plays a critical role in producing a high-quality die. By understanding the die making process, manufacturers and engineers can optimize their production processes, reduce costs, and improve product quality. Whether it's a simple die or a complex one, the die making process is an essential component of modern manufacturing.