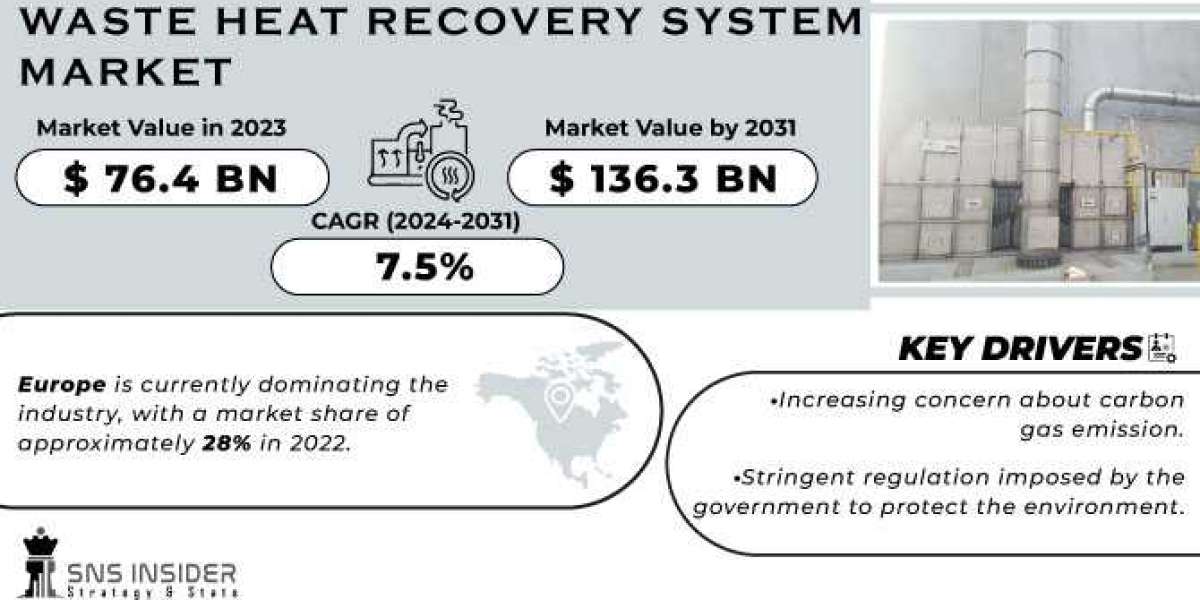

Waste heat recovery systems are designed to capture excess heat generated in various industrial processes and convert it into useful energy, such as electricity or heating. With energy costs on the rise and stricter environmental regulations, waste heat recovery is becoming essential for industries aiming to achieve cost savings and carbon reduction. This market is witnessing increased adoption as companies recognize the economic and environmental benefits of recovering waste heat.

The market’s growth is further supported by advancements in heat exchanger technologies, the adoption of organic Rankine cycle (ORC) systems, and integration with renewable energy systems. These innovations are enabling more efficient heat recovery and utilization, driving interest and investment in waste heat recovery solutions.

Key Market Drivers

- Stringent Environmental Regulations: Governments and environmental bodies worldwide are imposing regulations to reduce carbon emissions and energy waste. Waste heat recovery systems provide a solution for companies to achieve compliance with these regulations.

- Rising Energy Costs: With the increase in energy prices, industries are turning to waste heat recovery to lower their energy bills and improve overall operational efficiency.

- Industrial Expansion: The expansion of energy-intensive industries such as chemicals, cement, and steel is driving demand for waste heat recovery systems to optimize energy use and reduce operating costs.

- Sustainability Goals: Companies are increasingly focused on sustainability and corporate social responsibility. Waste heat recovery helps organizations reduce their carbon footprints and align with global sustainability goals.

- Technological Advancements: Innovations in waste heat recovery technologies, including improved heat exchanger materials and ORC systems, are enhancing the efficiency of heat recovery systems, making them more attractive to industries.

Market Segmentation

The Waste Heat Recovery System Market can be segmented by application, end-use industry, technology, and region.

By Application

- Steam and Power Generation: Waste heat recovery is widely used in steam and power generation, where recovered heat is converted into electricity or used for heating processes in industries.

- Preheating: Preheating of combustion air or other materials using waste heat reduces the energy demand in furnaces, kilns, and other high-temperature equipment.

- Others: Waste heat is also recovered for various applications, such as district heating and combined heat and power (CHP) systems, improving energy efficiency across multiple industries.

By End-Use Industry

- Cement Industry: The cement sector is a significant user of waste heat recovery systems, as it involves high-temperature processes that generate substantial waste heat.

- Oil and Gas: Waste heat recovery is increasingly adopted in oil refineries and natural gas processing facilities to reduce energy consumption and greenhouse gas emissions.

- Chemicals and Petrochemicals: Energy-intensive chemical processes produce large amounts of waste heat, which can be recovered to reduce energy costs and emissions.

- Metal Processing: The metals industry, especially steel production, generates a significant amount of waste heat, which can be utilized in preheating and power generation applications.

- Power Generation: Power plants, particularly combined-cycle plants, use waste heat recovery systems to maximize energy output and efficiency.

By Technology

- Heat Exchangers: Heat exchangers are widely used to capture and transfer waste heat. Innovations in exchanger designs and materials are enhancing heat recovery efficiency.

- Organic Rankine Cycle (ORC) Systems: ORC systems are gaining popularity for waste heat recovery, as they can convert low-temperature heat into electricity, expanding the scope of applications.

- Thermoelectric Generators (TEGs): TEGs use semiconductor materials to convert waste heat directly into electricity, representing an emerging technology with potential for widespread adoption.

- Steam Rankine Cycle: This technology uses steam generated from waste heat to drive turbines for electricity production and is commonly used in power generation applications.

Regional Analysis

- North America: North America is a major market for waste heat recovery systems, driven by stringent regulations on emissions and energy efficiency in industries such as manufacturing and power generation. The U.S. is at the forefront, with industries adopting waste heat recovery to cut costs and meet environmental standards.

- Europe: Europe is a leading market due to strict regulations on emissions and energy efficiency. Countries such as Germany and the U.K. are focused on industrial decarbonization, driving demand for waste heat recovery systems in heavy industries like chemicals, cement, and metal processing.

- Asia-Pacific: The Asia-Pacific region is experiencing rapid growth in the waste heat recovery market due to industrial expansion in countries like China, Japan, and India. With rising energy costs and growing environmental awareness, industries are increasingly adopting waste heat recovery technologies.

- Middle East Africa: In the Middle East and Africa, waste heat recovery is gaining traction in the oil and gas and petrochemical sectors. Countries such as Saudi Arabia and the UAE are exploring waste heat recovery systems as part of their broader energy efficiency and sustainability initiatives.

- Latin America: Latin America is an emerging market for waste heat recovery, with countries such as Brazil and Mexico investing in energy efficiency solutions across industrial sectors, particularly in cement and oil refining.

Read Complete Report Details of Waste Heat Recovery System Market: https://www.snsinsider.com/reports/waste-heat-recovery-system-market-2793

Current Market Trends

- Integration with Renewable Energy: Waste heat recovery is increasingly being integrated with renewable energy systems to optimize energy use and minimize emissions, aligning with global sustainability goals.

- Increased Adoption of ORC Technology: Organic Rankine Cycle technology is gaining traction for its ability to convert low-temperature waste heat into electricity, providing an efficient solution for industries.

- Focus on Industrial Decarbonization: As industries face pressure to reduce emissions, waste heat recovery is becoming a key strategy for decarbonization, particularly in sectors like cement and steel production.

- Government Incentives: Various governments are offering incentives to encourage industries to adopt waste heat recovery systems as part of broader energy efficiency and environmental initiatives.

- Technological Innovation in Heat Exchangers: Advances in heat exchanger technology, including improvements in materials and design, are enhancing the efficiency of waste heat recovery systems, making them more accessible to diverse industries.

About Us:

SNS Insider is a global leader in market research and consulting, shaping the future of the industry. Our mission is to empower clients with the insights they need to thrive in dynamic environments. Utilizing advanced methodologies such as surveys, video interviews, and focus groups, we provide up-to-date, accurate market intelligence and consumer insights, ensuring you make confident, informed decisions.

Contact Us:

Akash Anand — Head of Business Development Strategy

info@snsinsider.com

Phone: +1–415–230–0044 (US) | +91–7798602273 (IND)